GP-PRO SP-G Series

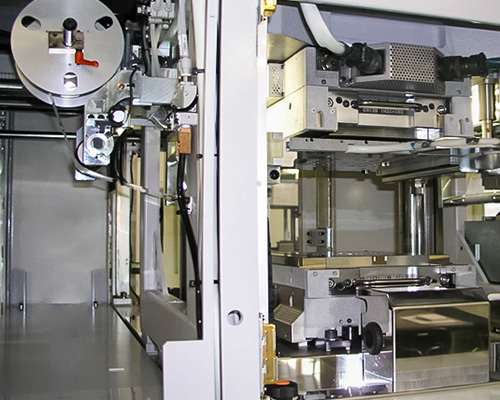

Thorough pursuit of dust protection

Automatic molding for automotive semiconductor quality

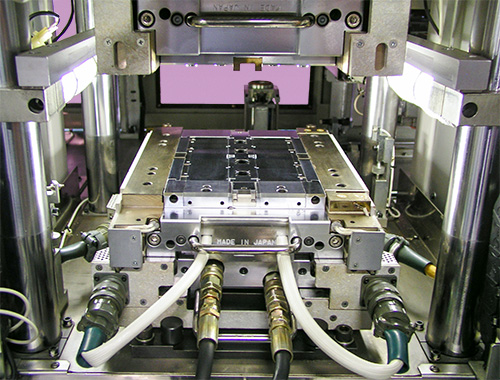

Since we started to sell the world's first automatic molding machines in 1980, we have accumulated 40 years of history and proven results. The SP-G, which is a state-of-the-art technology that was born based on the frequently upgraded "SP series", was made in order to solve the challenges of domestic and international customers.

The lineup includes three models—the 80-ton, 120-ton and 170-ton—and are designed to meet a wide range of needs for high quality, including connections to IoT devices, as well as resin sealing for consumer ICs, automotive ICs, and passive components through thorough dust protection.

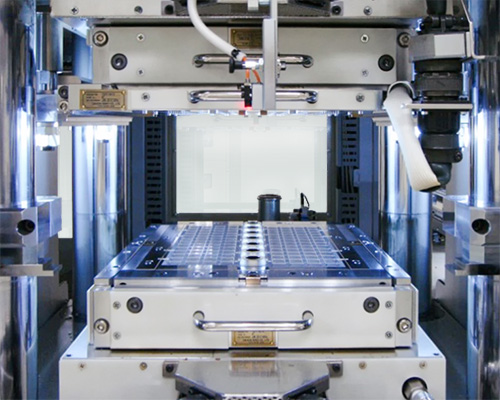

Feature 1: Dust protection to improve product quality

By installing a dedicated dust collection unit which encloses the parts feeder, dust generation has been reduced by 80% compared to a conventional one.

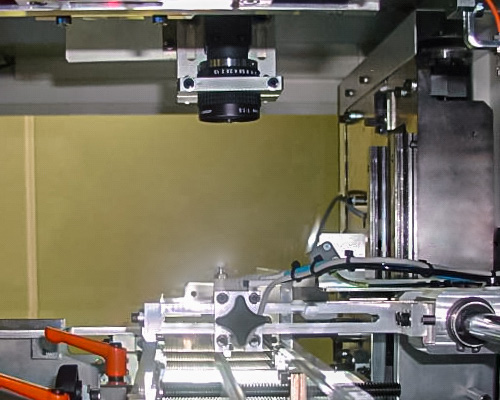

Providing the linear drive for the loader also solves dust risk and eliminates the risk of failure.

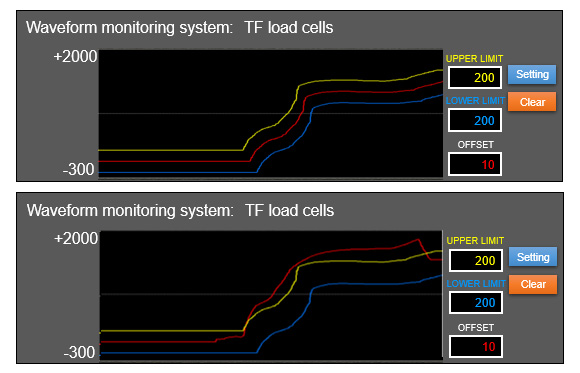

Feature 2: IoT ready for stable production

Real-time visibility into operation conditions required by smart factories is realized. (Optional)

Always-on monitoring provides alerts in advance to eliminate the risk of unexpected machine stoppages. We support customers' predictive maintenance activities.

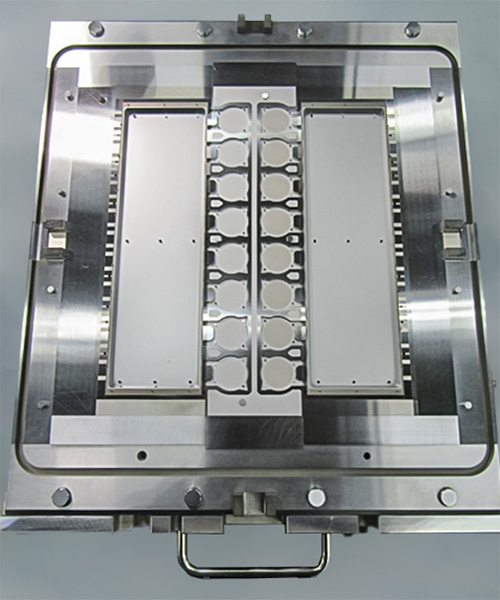

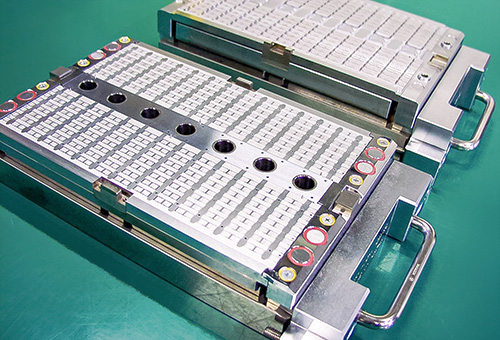

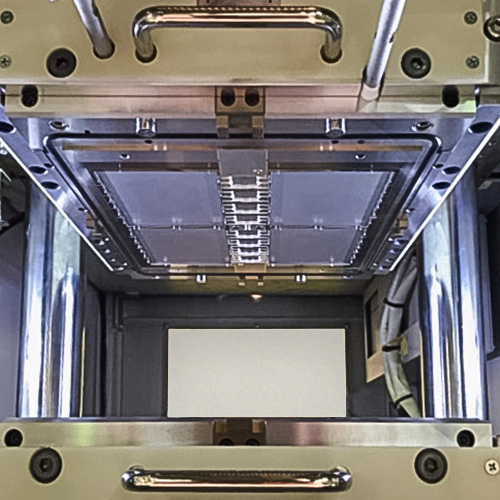

Feature 3: Dual-pot molds for larger products

In addition to conventional single-pot molds, the lineup includes dual-pot molds. They are compatible with large products that use large volumes of resin.

AI temperature prediction control technology improves mold temperature drop in real time. (Patent pending)

Feature 4: Customizable (individual molds, heat sink molds)

Our automated technology allows customers to customize their equipment to meet their needs and product characteristics, enabling full-automatic production.

We offer a variety of solutions including molding machines with individual-piece alignment and molding machines with insert units, in order to support products such as ECU boards, passive components, power modules, and devices with heat sinks, which are different from the typical lead frame.

Feature 5: Wide range of standard equipment

Movable frame pre-heater

Image processing product differentiation

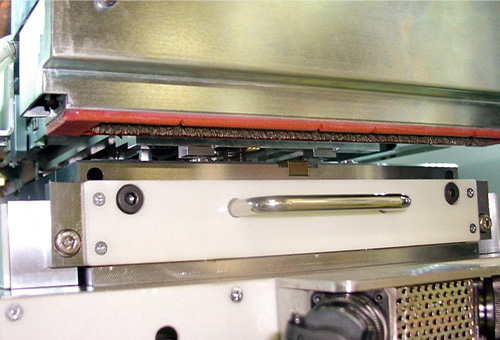

Powerful mold cleaner with rotating brush

Compatible with HD frames

Feature 6: A variety of molding options

HFC (bottom-mold movable CAV system)

VAM (vacuum assisted molding)

PPG (Top gate system)

FAM (Film assisted system)

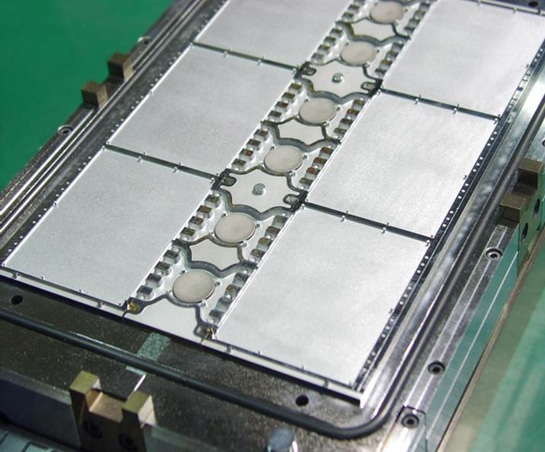

CCFC (Transfer compression)

CCFC is our unique technology that combines the benefits of transfer molding and compression molding.

By moving the top cavity of the mold in accordance with the resin filling timing, we can achieve narrow-gap thin molding, which is not possible with conventional transfer molding, and we can also make significant contributions to cost reductions by realizing filmless molding.

Specifications

| Clamp Force | Model Name(press) | Machine Size(mm) | Weight | Max. L/F Size(mm) | |

|---|---|---|---|---|---|

| 170ton | GP-PRO4 SP170G | (2press) | W:3500×L:1520×H:2020 | 10.5ton | 110×300 |

| GP-PRO8 SP170G | (4press) | W:4900×L:1520×H:2020 | 17.5ton | ||

| 120ton | GP-PRO4 SP120G | (2press) | W:3380×L:1520×H:1820 | 9.5ton | 90×275 |

| GP-PRO8 SP120G | (4press) | W:4940×L:1520×H:1820 | 15.5ton | ||

| 80ton | GP-PRO4 SP80G | (2press) | W:3180×L:1520×H:1820 | 7.5ton | |

| GP-PRO8 SP80G | (4press) | W:4540×L:1520×H:1820 | 11.5ton | ||

List of products

Semiconductor molding machines

-

GP-PRO sf Series

A compact, full-automatic molding system dedicated to high-mix low-volume production.

The sf40 (one-strip type), and two sf120 models (two-strip type) are available.

-

GP-PRO sa Series

Automatically transfers the lead frame and resin to the mold which are then automatically processed.

After molding, the product is removed manually in a two-strip semi-automatic molding system.

-

GP-PRO LAB Series

A manual molding system that offers a wide range of options from development to specialized applications.

-

S・Pot

A molding machine for device development, which uses a compact mold. It is tabletop-ready, easy-to-handle, and has a small form-factor. Prototype molding can be made in a short period of time and at a low price, making it a flexible device for developing new packages.

-

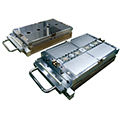

GP Molds

Precision molds for semiconductor packaging. Our unique Clamp Control Floating Chase (CCFC) and other mechanisms are available to handle all packages.

Semiconductor related equipment

-

TS-PRO

TS-PRO is a machine that is a global standard for applying Quad Flat No leaded package (QFN) back tape.

By applying back tape after wire bonding, the problems that occur relating to tape are solved, and it contributes to substantial cost reductions.

-

DS-PRO

A machine that automatically strips QFN back tape. Compatible with both slit and stack magazines. The machine automatically strips off tape that has been securely applied.