TS-PRO/DS-PRO

TS-PRO

Applying back tape after wire-bonding A machine that is a global standard for taping processes

The TS-PRO has the No.1 market share as a machine adopted by major Outsourced Semiconductor Assembly and Test (OSAT) companies, particularly in Taiwan, China and Japan.

Using our unique taping technology (patented), quality and cost issues regarding the QFN package can be improved, traditionally associated with the pre-tape method. The TS-PRO WIDE is also available with a frame width of 100 mm for HD.

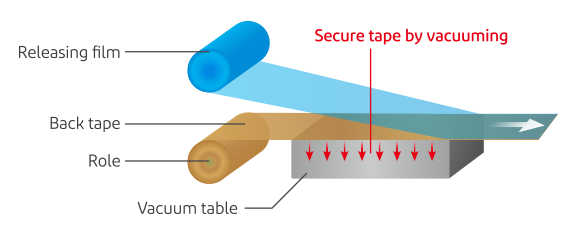

Feature 1: Unique taping mechanism

The unique mechanism allows the tape to have suction applied and be pressurized so that the back tape can be applied without wire damage occurring to the installed lead frame.

Feature 2: Reduction of defects due to process changes

Tape is applied after plasma cleaning to reduce the amount of dust that adheres to the frame and to reduce resin leakage (flash).

The pre-tape method results in wire-bonding failure due to the tape, but the TS-PRO can be introduced to change the process order so that wire-bonding failure due to tape does not occur.

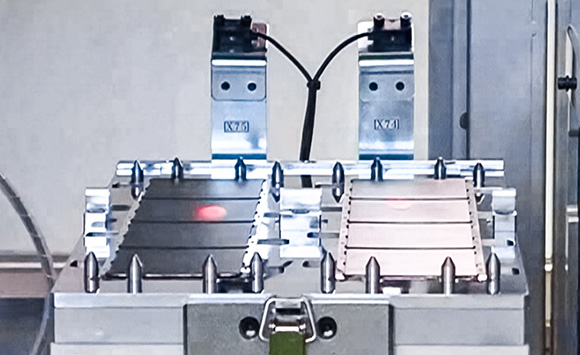

DS-PRO

Realization of labor savings in the De-TAPE process Quick peeling at a speed of about 11 seconds per piece of tape

The DS-PRO is a piece of equipment that allows the lead frame to be automatically removed from the magazine and the tape to be peeled with full automation.

It is compatible with both slit and stack magazines for stable tape peeling.

Feature: Pre-heat unit

Prevents tape cutting by warming up the tape with the pre-heater and loosening the adhesive layer before tape peeling.

By setting the desired tape peeling speed and pre-heat time, you can identify the best tape peeling conditions and peel the tape off quickly and cleanly.

Specifications

| Model Name | Machine Size(mm) | Weight | Max. L/F Size(mm) |

|---|---|---|---|

| TS-PRO | W:1550×L:1420×H:1820 | 1.9ton | 75×270 |

| TS-PRO WIDE | W:1750×L:1420×H:1820 | 1.9ton | 100×300 |

| DS-PRO | W:840×L:1380×H:1820 | 0.9ton | 75×270 |

List of products

Semiconductor molding machines

-

GP-PRO SP Series

An automatic molding system suitable for mass production.

The company has implemented thorough dust protection to enhance reliability and meets a wide range of needs for high quality, from consumer ICs to automotive ICs and passive components.

-

GP-PRO sf Series

A compact, full-automatic molding system dedicated to high-mix low-volume production.

The sf40 (one-strip type), and two sf120 models (two-strip type) are available.

-

GP-PRO sa Series

Automatically transfers the lead frame and resin to the mold which are then automatically processed.

After molding, the product is removed manually in a two-strip semi-automatic molding system.

-

GP-PRO LAB Series

A manual molding system that offers a wide range of options from development to specialized applications.

-

S・Pot

A molding machine for device development, which uses a compact mold. It is tabletop-ready, easy-to-handle, and has a small form-factor. Prototype molding can be made in a short period of time and at a low price, making it a flexible device for developing new packages.

-

GP Molds

Precision molds for semiconductor packaging. Our unique Clamp Control Floating Chase (CCFC) and other mechanisms are available to handle all packages.