Virtual Plant Tour

Watch the video below to learn about I-PEX manufacturing.

I-PEX Virtual Factory Tour Video

What is I-PEX manufacturing

How connectors are made

How semiconductor molding equipment is made

What is I-PEX manufacturing

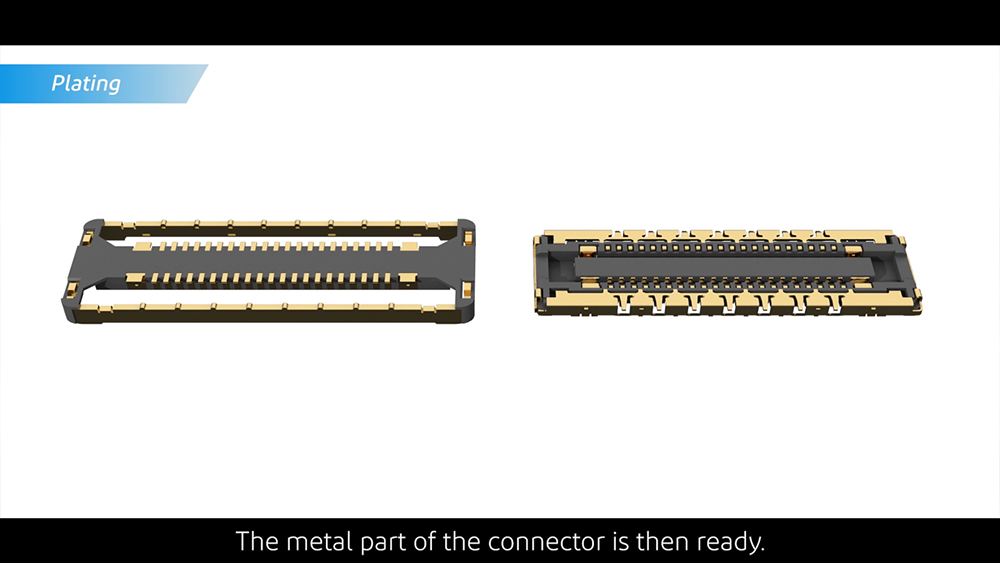

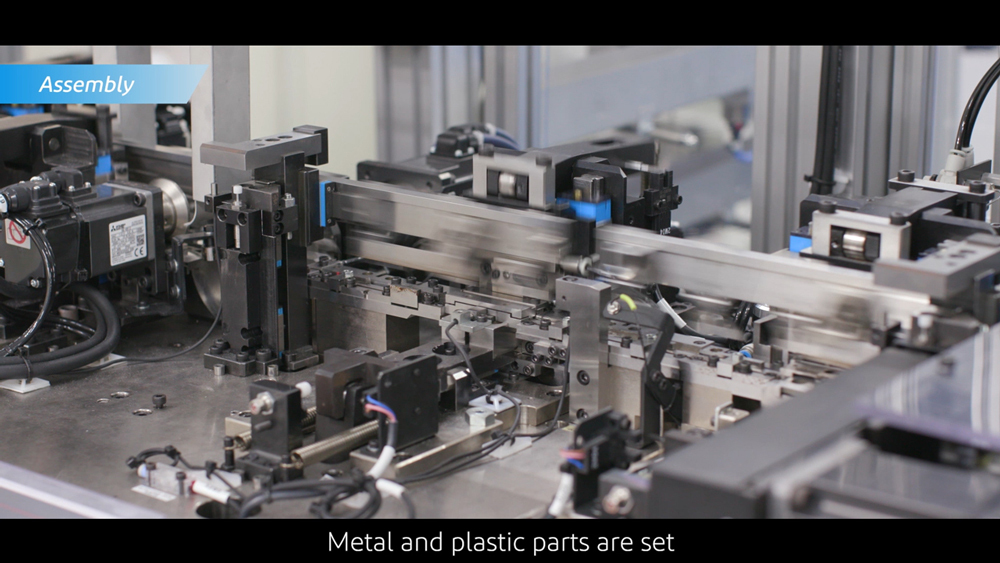

How connectors are made

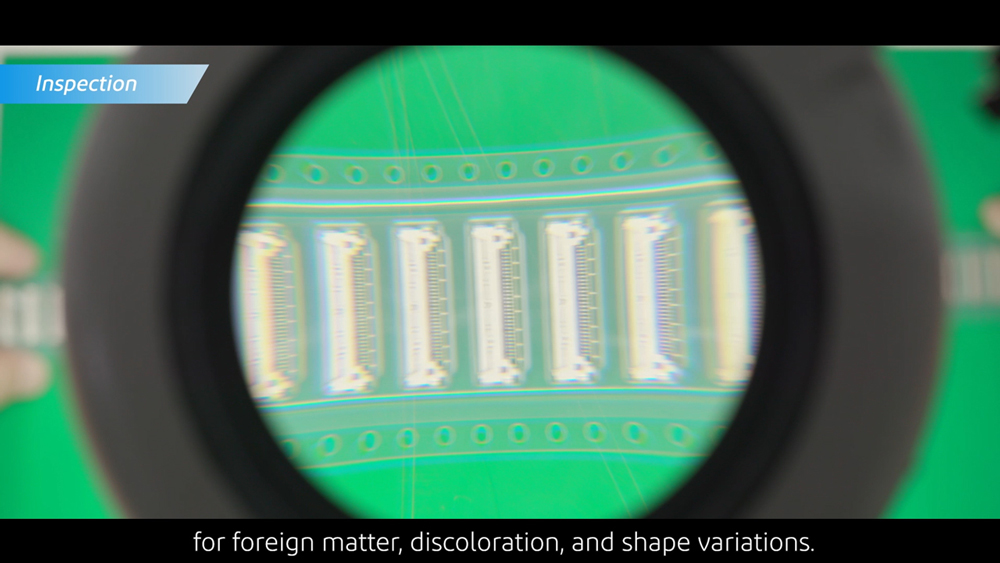

Connectors are inspected prior to shipment. Visual inspections are conducted to check for foreign matter, discoloration, and shape variations, and sample dimensions are measured using a microscope.

After the inspection process, the connectors are packed for shipment.

The shipped I-PEX connectors are in products worldwide.

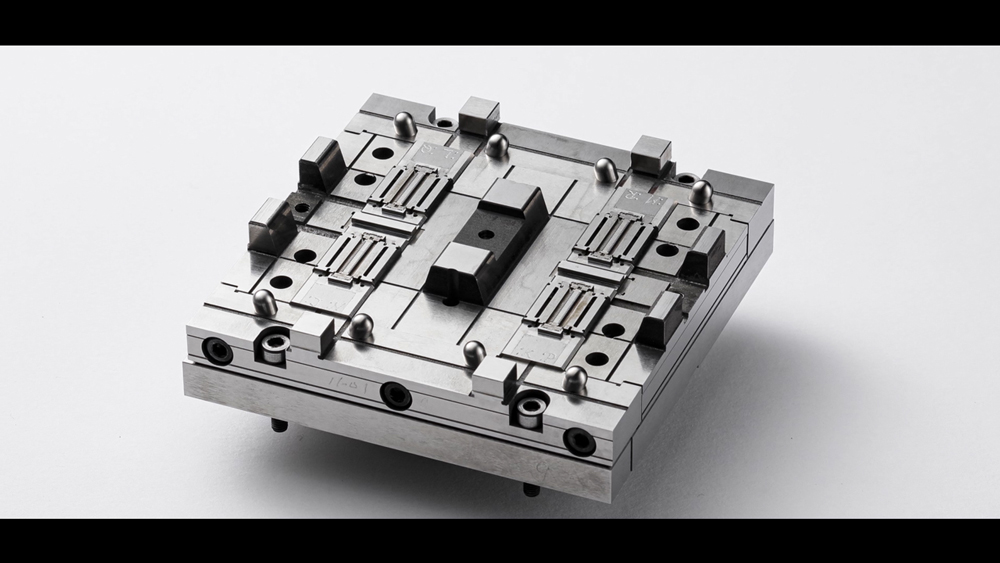

How semiconductor molding equipment is made

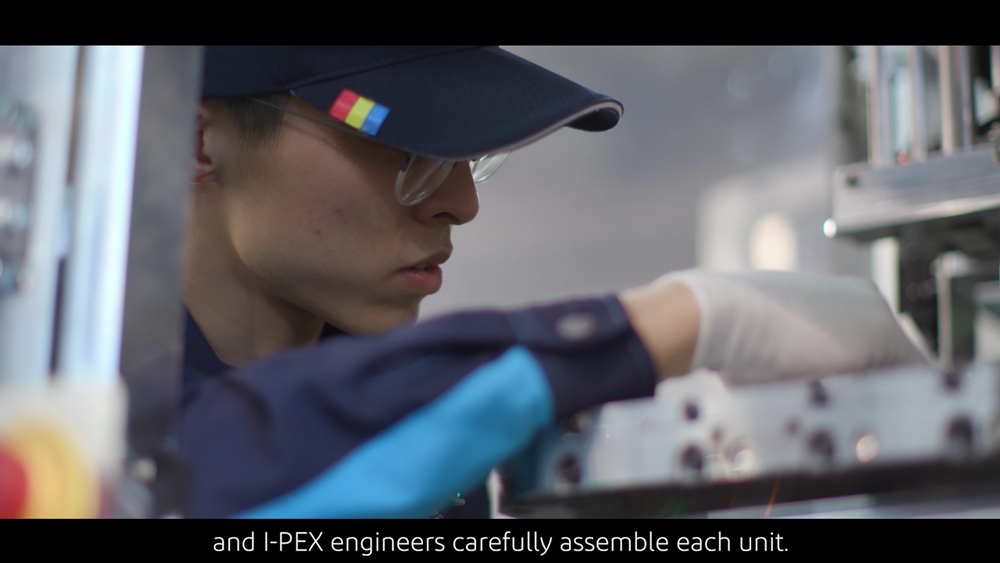

One of the processes for manufacturing semiconductors, which are indispensable for electronic devices, is “molding,” in which the semiconductors are covered with black plastic.

I-PEX designs, manufactures, and sells equipment that performs this “molding” process automatically.

The completed equipment is supporting the manufacture of semiconductors that are indispensable for all kinds of electronic devices.