Nov. 8, 2022

Drone safety

The time has come for drones to be a common occurrence in the sky.

Considering that a drone crash can lead to the serious injury,every part used in a drone must be of absolute quality and high reliability.

One such component is the connector which supplies power to the drone.

Battery connector requirements

- 1.Prevent unmating due to vibrations or shock

- 2.Immediate removal of the battery from drone in case of emergency

- 3.Prevent half-mating

- 4.Prevent damage to housing and terminals caused by slant mating and strong shock

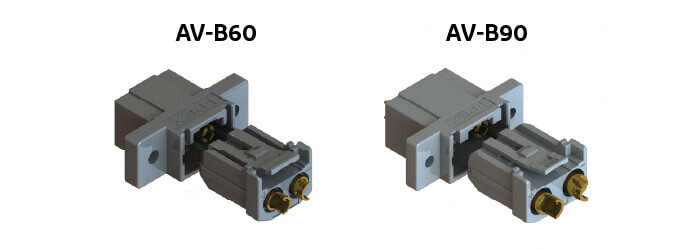

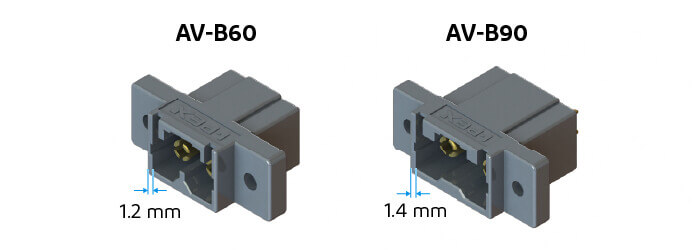

I-PEX is currently developing new Li-Po battery connectors (AV-B60/AV-B90) that meets all of these requirements and contributes to safe drone navigation.

Mating lock

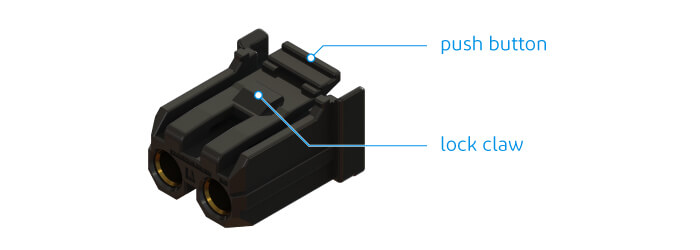

The I-PEX AV-B series is equipped with a mating lock mechanism.

This prevents unintentional mating disengagement due to vibration and shock during a drone flight.

Emergency extraction

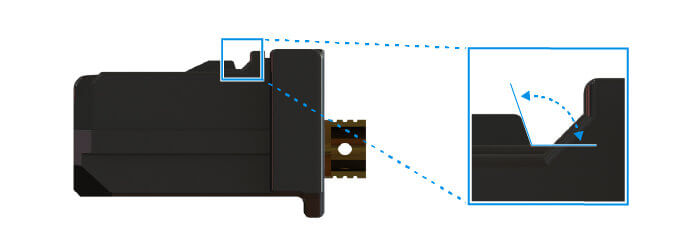

On the other hand, the shape (slope) of the lock claw is designed so that the battery can be immediately removed from the drone during unusual conditions with the drone or the battery.

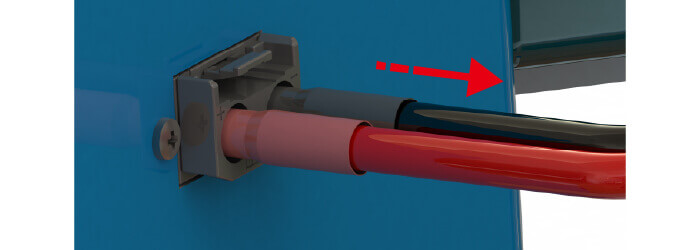

In an emergency, the power can be quickly disconnected by pulling the wire with a constant force without operating the lock function.

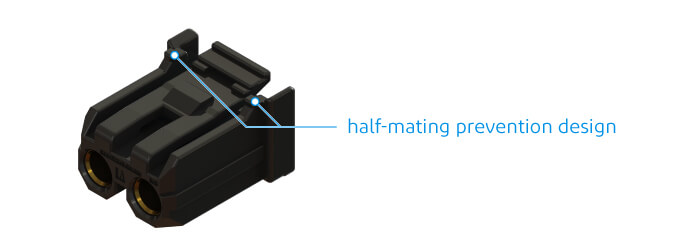

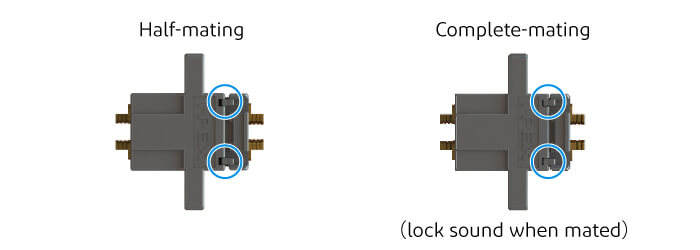

Half-mating prevention

The half-mating prevention design allows for visual confirmation of correct mating. In addition, the lock sound enables auditory confirmation that it is mated.

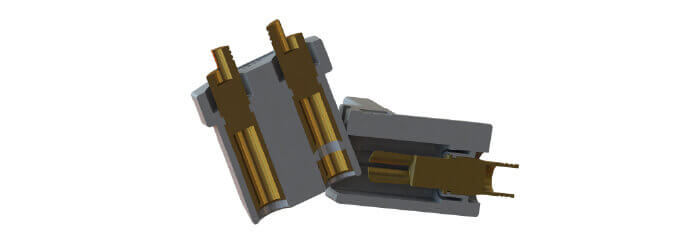

Countermeasures against slant mating

No matter what angle in which the housing is inserted, it cannot touch the internal terminals. This design prevents damage and deformation of terminals due to slant mating.

Furthermore, the housing is made stronger by increasing the thickness of the housing at the front of the connector. This prevents the housing from cracking or breaking due to slant mating.

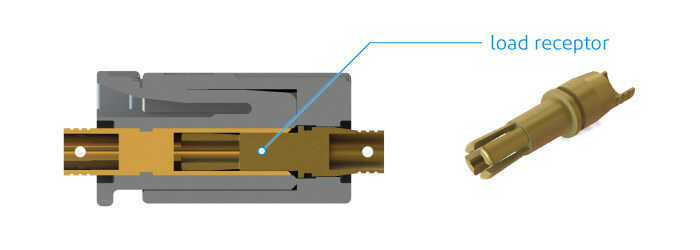

Prevention of terminal deformation

A load receptor is provided at the base of the terminal spring. This structure minimizes the load on the terminal spring in the event of drone crash and/or collision. It prevents the deformation of the terminal spring and maintains the stable power supply.

I-PEX AV-B connector series Specification

AV-B60 |

AV-B90 |

|

|---|---|---|

| Current Rating |

40A (Inrush 60A) per connector (above spec. under AWG #12) |

70A (Inrush 90A) per connector (above spec. under AWG #8) |

| Pin Count |

2 |

2 |

| Operating Temperature |

-40℃~120℃ |

-40℃~120℃ |

| Wiring Method |

Soldering |

Soldering |

| Applicable Cable Size |

AWG #12-16 (1.25sq-3.5sq) |

AWG #8-12 (3.5sq-8sq) |

| Anti-Spark Function |

No |

Yes |

| Insertion Force |

Less than 30N |

Less than 40N |

| Unmating Force |

Less than 30N |

Less than 30N |

| Retention Force |

More than 60N |

More than 60N |

| Withstand Voltage |

500V DC |

500V DC |

*The content of this article is subject to change without notice as a result of any changes in connector specification.