Products & Services

I-PEX Philippines Inc. is committed to delivering solutions with precision and speed. We understand that our customers and partners rely on us for quality and efficiency, and we strive to exceed expectations in every project we undertake. From concept to completion, we focus on accuracy, timeliness, and innovation to ensure that our products and services create real value.

This commitment is guided by our Code of Conduct, which shapes how we work every day:

- Customer/Partner-first—We prioritize the needs of those we serve. We venture a step beyond the needs of the times to create new value.

- Challenge Current Practices—We embrace change and seek better ways to do things.

- One Challenge A Day—Continuous improvement starts with small, daily steps.

- Think Deep, Act Fast—We combine thoughtful analysis with swift execution.

- Disagree with Respect—Diverse ideas lead to stronger solutions.

- Collaborate to Create Value—Teamwork drives innovation and success.

- Grit and Perseverance—We keep going until we achieve success.

Our products and services are more than just deliverables; they reflect these principles in action.

Our Expertise

Precision Components

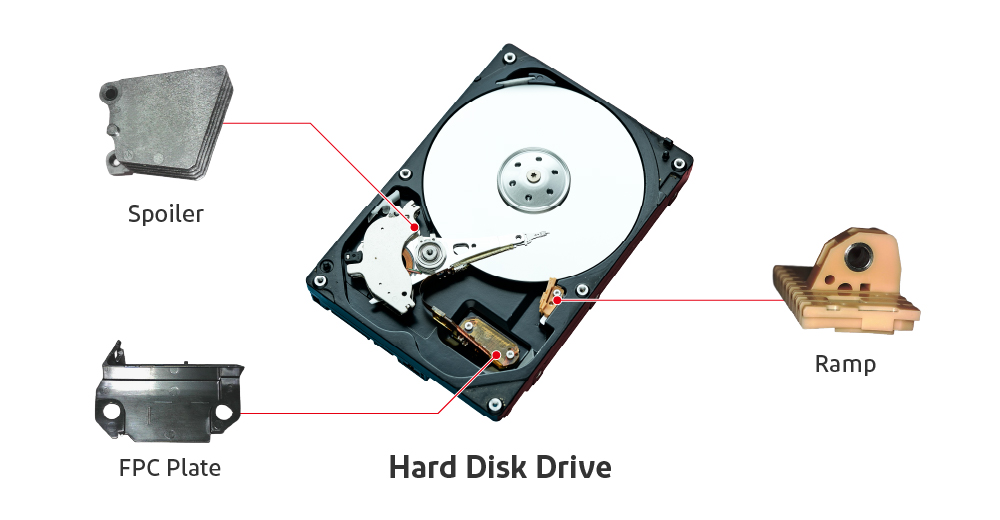

HDD Parts

Our plastic-injected HDD components are produced using high-precision molds and tightly controlled injection parameters, ensuring consistent dimensional accuracy and mechanical stability.

Forensic Devices

Our medical-grade components meet strict regulatory standards to ensure safety, reliability, and flawless integration in life-saving devices.

Connectors

Automotive Connector

Built for performance and durability, our automotive connectors are engineered with exacting standards to ensure secure, high-conductivity connections in even the most demanding environments.

Production Area & Equipment

Injection Molding—Advanced plastic injection molding with high accuracy

Our Injection Molding area is equipped with over 40 advanced injection machines designed to produce high-precision components with consistency and efficiency. This section is the backbone of our manufacturing process, ensuring that every part meets strict quality standards. With cutting-edge technology and skilled operators, we deliver products that meet the demands of automotive and electronics industries worldwide.

Horizontal Injection Machines for Automotive Connectors

Horizontal Injection Machines for Automotive Connectors Vertical Injection Machines for HDD & Ramp

Vertical Injection Machines for HDD & RampAssembly—Skilled manual and automated assembly solutions

Our Assembly Area is where precision meets craftsmanship. This section is dedicated to putting together complex components with accuracy and care, ensuring that every product meets the highest quality standards. Skilled technicians work with advanced tools and processes to assemble parts efficiently while maintaining strict compliance with customer specifications. This area plays a vital role in transforming individual components into complete, reliable solutions ready for global markets.

Assembly of Hold down and Terminal of Automotive Connector Parts

Assembly of Hold down and Terminal of Automotive Connector Parts Camera Inspection of Automotive Connector Items

Camera Inspection of Automotive Connector ItemsInspection & Measuring—Comprehensive quality inspection and precision measurement

Our Inspection & Measuring area is dedicated to ensuring absolute precision in every component we produce. Equipped with advanced measuring instruments and state-of-the-art inspection systems, this section verifies dimensional accuracy, surface quality, and compliance with strict specifications. By combining technology with meticulous attention to detail, we guarantee that every product meets global standards for quality and reliability before it reaches our customers.

Dimension Measurement Using TMS

Dimension Measurement Using TMS Measuring Using Smart Scope

Measuring Using Smart Scope Manual Inspection of Automotive Connector Items

Manual Inspection of Automotive Connector Items Weighing Process of Automotive Connector Parts

Weighing Process of Automotive Connector PartsWashing—Specialized cleaning process to ensure contamination-free products

Our Washing area ensures that all components are thoroughly cleaned before moving to the packaging stage. Using specialized washing systems and controlled processes, we remove contaminants and residues to maintain the highest standards of quality and precision. This step is essential for achieving flawless assembly and reliable performance, especially for products used in sensitive applications like automotive and electronics.

Automatic Washing Machine

Automatic Washing Machine Deionized Water System

Deionized Water SystemForensic Analysis Device Assembly—Precision engineered, expertly assembled

We specialize in the precision engineering of advanced microfluidic devices used for forensic analysis. Each device is a complex integration of over 300 meticulously designed components which include molded microchannel parts, filters, valves, and chemicals. We bring these components together into a system that works flawlessly, delivering fast and accurate results for forensic analysis. Every stage of production shows our dedication to quality and innovation.

Forensic Analysis Device Inspection

Forensic Analysis Device Inspection  Forensic Analysis Device Cartridge Insertion

Forensic Analysis Device Cartridge Insertion Mold Service—Maintenance and service of injection molds for stable production

Our Mold Services area focuses on maintaining the integrity of molds used in production. While we do not manufacture molds, we provide thorough cleaning and minor repairs to ensure optimal performance and longevity. For major repairs and complex modifications, molds are sent to our specialized facility in Japan. This approach guarantees that every mold remains in excellent condition, supporting consistent quality and precision in our manufacturing process.

Mold Repair

Mold Repair Big Mold Repair

Big Mold Repair