I-PEX not only has injection molding technology for thermoplastic resin, but we also have transfer molding technology for thermoset resin.

We can provide a proposal on supporting the module development to the customer as one of the services of I-PEX’s “Manufacturing Solutions.”

Difference between Thermoplastic Resin and Thermoset Resin

What is thermoplastic resin?

Resin which solidifies by cooling during the molding phase. This resin will also melt again when reheated.

Since this resin is widely used in commodity items.

Ex. Polyphenylene sulfide(PPS), Polyethylene terephthalate

What is thermoset resin?

Resin which solidifies by heating during molding phase. This resin will NOT melts again when reheated.

This resin has a high resistance to heat and strength that it is widely used in industrial items.

Ex. Epoxy, Phenol

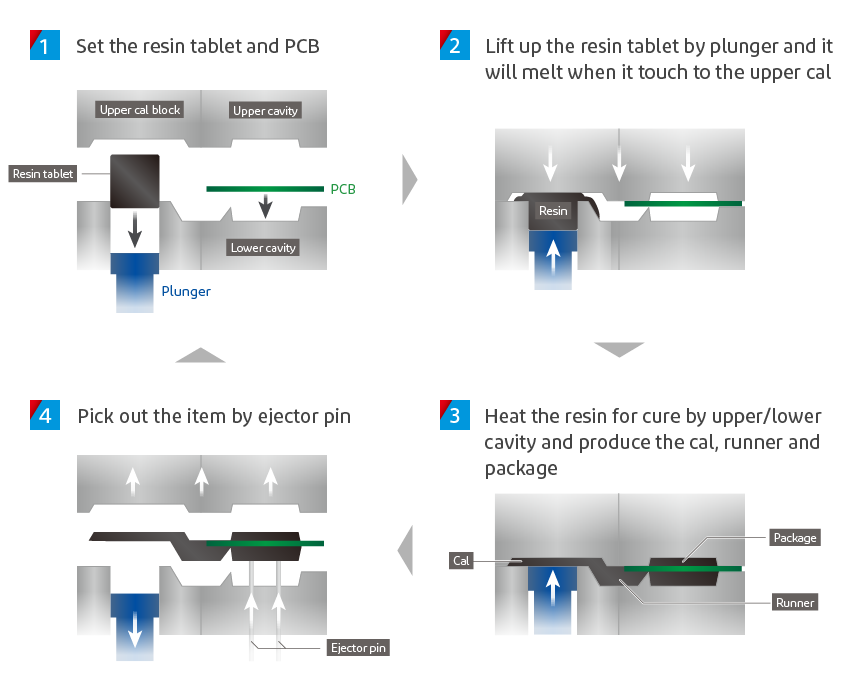

What is transfer molding?

It is a molding method for thermoset resin, whereby the resin is heated and injected into the cavity using a plunger. The mold is then reheated to solidify the resin.

It has characteristics on high dimension stability and less burr occurrence.

Process of Transfer Molding

Process of Transfer MoldingThermoset Resin Molding Enables Lightening and Miniaturization Automotive Components

Demand of Automotive Components:Lightening and Miniaturization

Although EV is attracting attention because it runs on electricity and does not emit CO2, it is not suitable for long-duration driving compared to gasoline-powered vehicles.

Under the recent environmental regulations, every OEM is investing their resources for R&D on EV to expand the market with the purpose of decreasing CO2 emissions.

Therefore, "lightening and miniaturization of automotive parts" is one of the biggest factors for ongoing EV development.

I-PEX is undertaking this "lightening and miniaturization of automotive parts" issue by using thermoset resin molding technology.

Characteristics on Thermoset Resin Molding in I-PEX

- Ability to directly overmold PCB for ECU

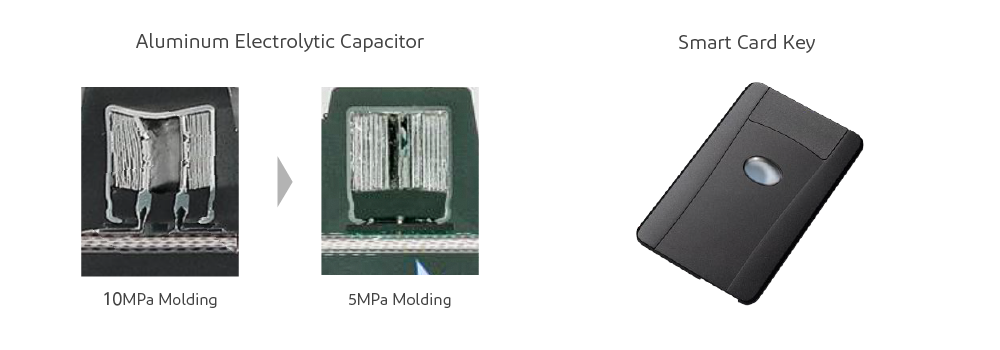

- Decreases damage to inserted parts by low pressure molding

- Highly water proof

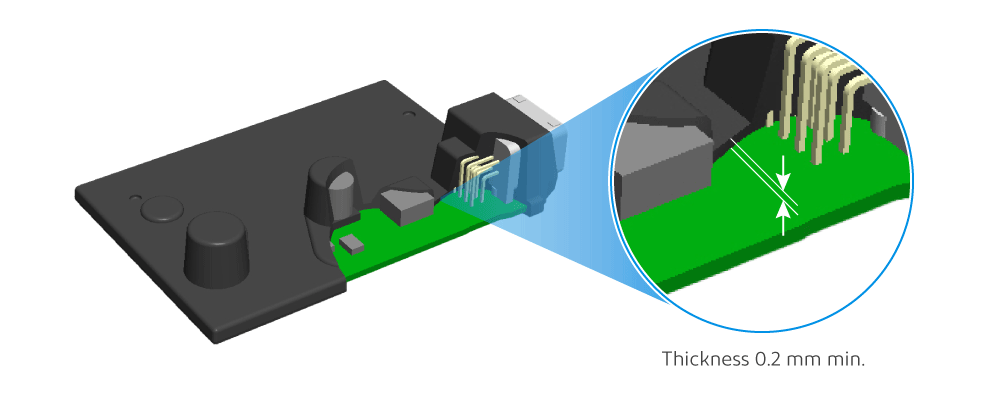

- Thin molding(0.2 mm~)

- Thermal conductivity more than 0.8W/m・K

- Easy finishing with less burr

Molding Example:ECU PCB Encapsulation

The material is very strong, making it possible to directly encapsulate and mold an ECU board, reducing many attachment parts such as collars, which helps produce a compact size.

Upon customers’ request, we can also mold a connector part integrally with thermoset resin. Furthermore, since our cured resin has an excellent finish, it can be applied to design products such as smart card keys.

Molding Example: ECU PCB Encapsulation

Molding Example: ECU PCB Encapsulation Molding Example: Thin Molding

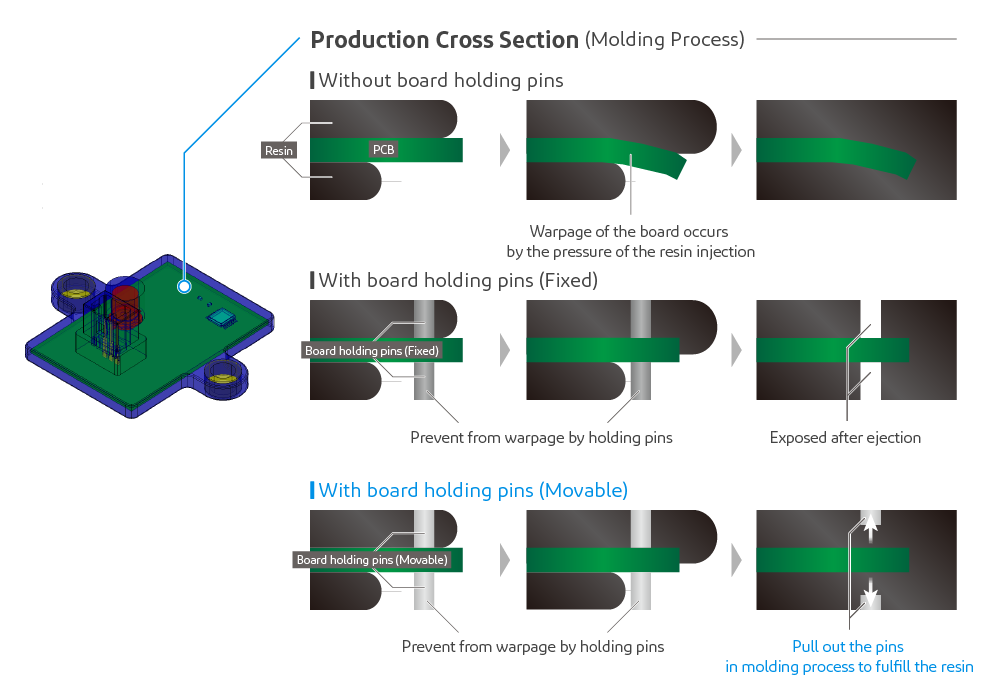

Molding Example: Thin MoldingBoard warpage impedes the product functions' stability and can cause product defects. Our pultrusion technology allows us to pull out the board holding pins during the product molding process, thereby completely sealing the board, and minimizing warpage.

Realizes the complete encapsulation by pultrusion

Realizes the complete encapsulation by pultrusionProposal from Production Concept Stage

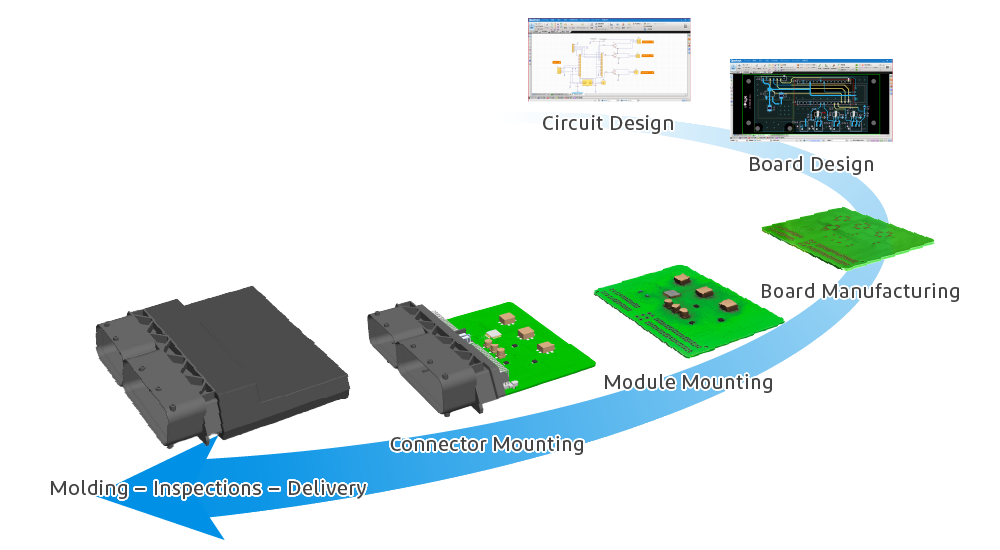

I-PEX provides not only a simple molding technology, but also has integrated production from circuit design, board design, and board mounting of module products. We will work with you from concept to production phases.

Automotive Components Solution of I-PEX

Automotive Components Solution of I-PEX