Our Company

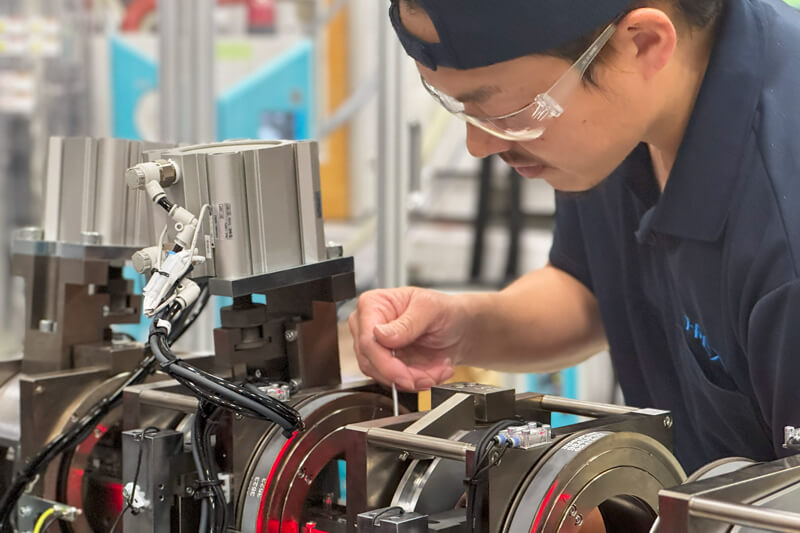

Our capabilities in Alabama include injection molding, insert molding, connector stitching, and metal stamping, conducted by experts with more than 20 years of experience in the USA. This is backed by I-PEX Group, which has been in operation for more than 60 years and has experience in life sciences, aerospace, digital applications, automotive, semiconductor, and other cutting-edge industries.

The way we deliver our service and value at I-PEX can be unique. Some may think of us as crazy, for asking so many questions. Inefficient for providing custom-built production lines tailored for each customer. Troublemaker for saying no to our customers.

We believe this is all necessary, to maximize your potential and deliver the greatest value.

For many of our customers, I-PEX is the last resort.

If you feel like giving up.

If you don't know where to start.

If you can't find anyone to shape your ideas into products.

I-PEX can help.

Because we do EVERYTHING to deliver quality products, on time.

Your success, no matter what.

About I-PEX USA Manufacturing Inc.

| Company Name | I-PEX USA Manufacturing Inc. |

|---|---|

| Establishment | December 2000 |

| Address | 239 Technology Parkway, Auburn, AL 36830 |

| Operation |

Injection Molding (Automated) Insert Molding (Automated) Connector Assembly Metal Stamping |

| Products |

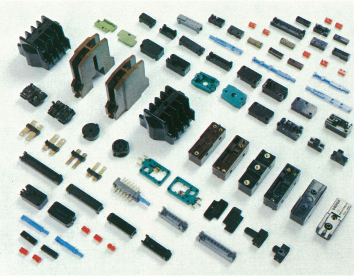

Precision plastic products: Connector, Electronics & Automotive parts |

| Land Space | 486,450 square ft (45,192 sq. meters) |

| Floor Space | 110,763 square ft (10,290 sq. meters) |

I-PEX USA Manufacturing Inc.

I-PEX USA Manufacturing Inc.

IATF 16949:2016

Certified

ISO 13485

Will Be Certified

(Ogori Plant, Japan)

About the Boston Office (I-PEX USA Components Inc.)

| Company Name | I-PEX USA Components Inc. |

|---|---|

| Establishment | August 2025 |

| Address | One Broadway, Floor 14, Cambridge, MA 02143 |

| Operation | Business Development |

Boston Office

Boston Office60 years in business, 22 years in the U.S.

1963: Foundation

Akira Konishi, Founder of I-PEX

Akira Konishi, Founder of I-PEXBecoming a Manufacturer of Connectors Using Precision Molds

Connector parts at that time

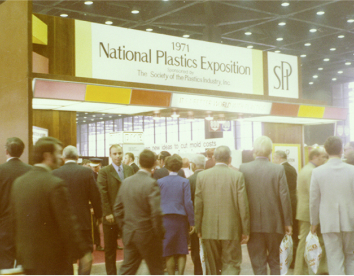

Connector parts at that timeFirst Japanese Mold Manufacturer to Exhibit at Chicago Trade Show

1971 National Plastic Exhibition

1971 National Plastic Exhibition2000: Touchstone Precision, Inc. Opens in Auburn, Alabama, U.S.A.

“I-PEX has more than 20 years of expertise in Asia; however, not in highly economically developed countries including the US. We will launch business in these countries to explore new business opportunities with our unique technologies and capabilities. We plan to start on a small scale, focusing mainly on precision insert molding. In the future, we plan to offer a flexible supply chain solution to meet our customers' needs.”

The company's name at the time, Touchstone*, was chosen as the intention was to test the company's technological capabilities in a highly developed market and economy. *Touchstone: a piece of fine-grained dark schist or jasper formerly used for testing alloys of gold by observing the color of the mark they made on it. In June 2002, about a year and a half after the establishment of the corporation, the factory started operations. Initially, the company was not well known and orders were scarce for a while, but thanks to the activities of the sales office established in Detroit, the company was awarded its first order for molded products. Thereafter, I-PEX received orders from Japanese auto parts manufacturers and began producing insert-molded products and connectors for the automotive industry.

Founding of Touchstone Precision, Inc.,

Founding of Touchstone Precision, Inc., an advance of I-PEX USA Manufacturing, Inc.

Company Growth and Expansion

We are now positioned to serve not only the automotive but various other industries including aerospace, life sciences and more.

Completion ceremony of I-PEX USA Manufacturing, Inc. Building 3

Completion ceremony of I-PEX USA Manufacturing, Inc. Building 3Gallery

Video

I-PEX USA Manufacturing Inc.

I-PEX USA Manufacturing Inc.

-

I-PEX USA Manufacturing Invests $3 Million in Auburn, Alabama

- I-PEX USA Manufacturing Inc.

- Corporate

-

I-PEX USA Manufacturing Inc. showcases manufacturing solutions for BEV components at The Battery Show South 2025

- Exhibition

- I-PEX Solutions

- Automotive Components

- I-PEX USA Manufacturing Inc.

-

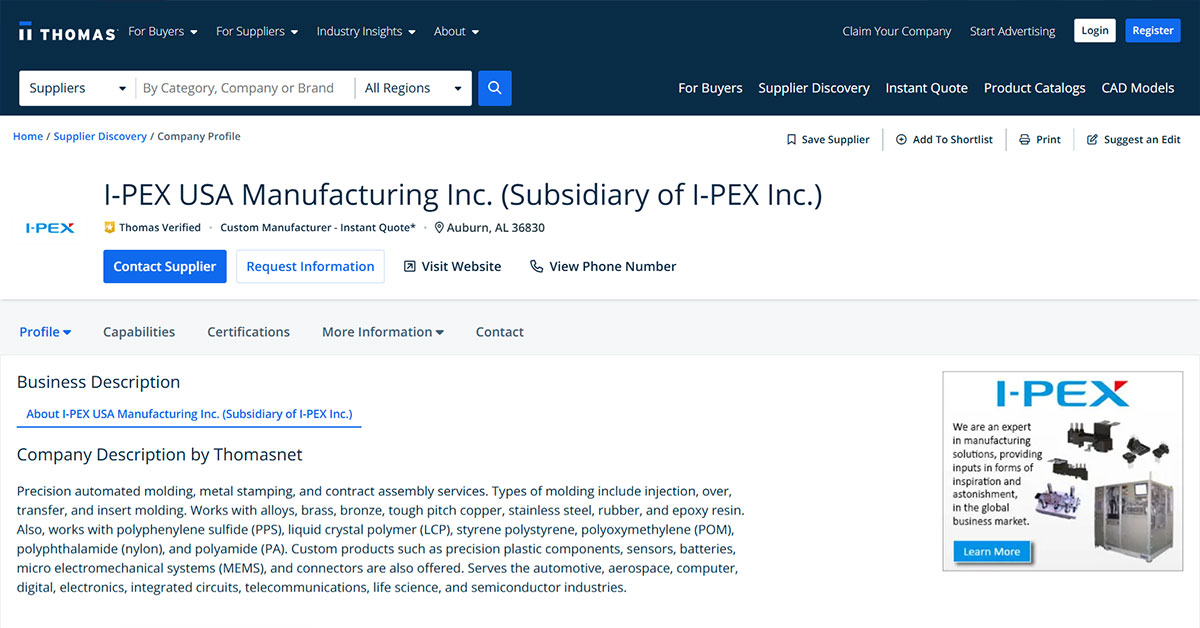

I-PEX USA Manufacturing Inc. is now available on Thomasnet®.

- I-PEX USA Manufacturing Inc.

- I-PEX Group Network

-

Join Our Team in Auburn, Alabama—Recruitment Page Now Open!

- I-PEX USA Manufacturing Inc.