Precision Manufacturing for the Automotive Industry

We ensure quality at every step, from in-house tool design to fully automated manufacturing and inspections for products qualified for the automotive industry.

Our story begins with precision manufacturing.

In 1963, we developed the module mold manufacturing system. This includes splitting the mold core into multiple parts, hardening with heat treatment, and a fully automated mold manufacturing process.

During this period, we also created high-performance quenching molds for computers, integrated circuits, telecommunications devices and more.

Our molds are high-precision, split in structure by combining small mold inserts, manufactured with our grinding technology.

Interchangeability of mold inserts provides our customers with high precision stability and flexibility. It allows replacing of only the damaged parts of the mold, rather than the entire mold. It also offers design versatility, accomodating different product designs with a minimum changeover.

Combining different technologies including molds, press dies and automation, designed and fabricated in-house, ensures high quality and supports high volume production.

For cost efficiency, production sites are chosen taking into consideration product specifications and production volume.

By combining these technologies and capabilities, we provide quality products with stable mass production and delivery for both North America and global customers from Alabama.

We continue to pursue precision manufacturing, advanced product/tooling development and solutions to keep inventions and innovations moving forward.

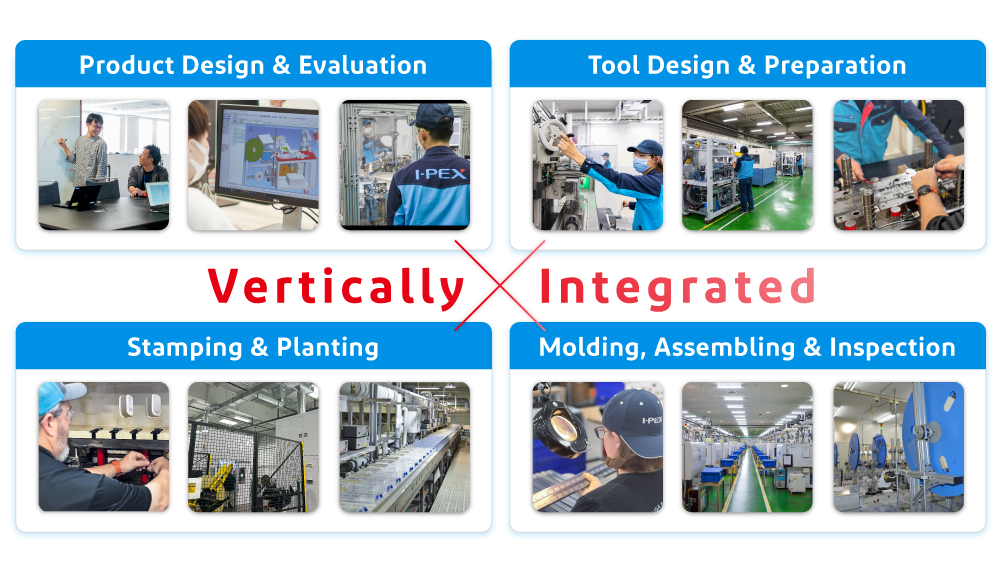

Vertically Integrated Production System

We utilize a variety of manufacturing methods and molding technologies in conjunction with resin materials to produce reliable, high-quality products. By carefully managing every aspect of the production process, we guarantee seamless integration and exceptional product quality across a range of industries.

Key Stages of Vertically Integrated Production

- Product Design & Evaluation: We provide comprehensive product design services, including evaluations, to ensure optimal performance before production starts.

- Tool Design & Preparation: Our in-house tool design and preparation capabilities enable us to create custom solutions tailored to specific manufacturing needs.

- Stamping & Plating: We offer precision stamping and high-quality plating services, essential for producing durable, high-performance components.

- Molding & Assembling & Inspection: Our advanced molding, assembly, and inspection processes ensure that the final product meets strict quality standards and customer specifications.

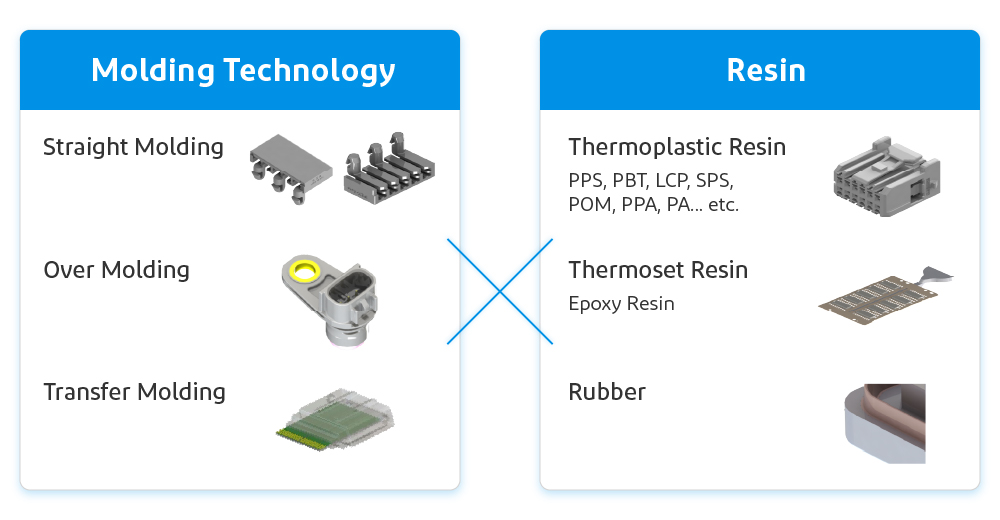

Precision Manufacturing Through Advanced Molding Technology and Resin Materials

We combine advanced molding technologies with high-performance resin materials to deliver reliable and superior products. This integration allows us to develop customizable solutions catering to various industries' specific requirements.

Molding Technologies

- Straight Molding: Utilizing standard injection molding techniques to produce precision parts efficiently.

- Over Molding: Combining different materials to create cohesive, multi-material components.

- Transfer Molding: Achieving high precision by molding substrates directly with resin for intricate structures.

Resin Materials

- Thermoplastic Resin: We utilize PPS, PBT, LCP, SPS, POM, PPA, and PA to produce parts that exhibit excellent heat resistance and chemical durability.

- Thermoset Resin: We use epoxy resin to create robust and durable components known for their high reliability.

- Rubber: Our products are made from rubber materials, offering flexibility and durability.

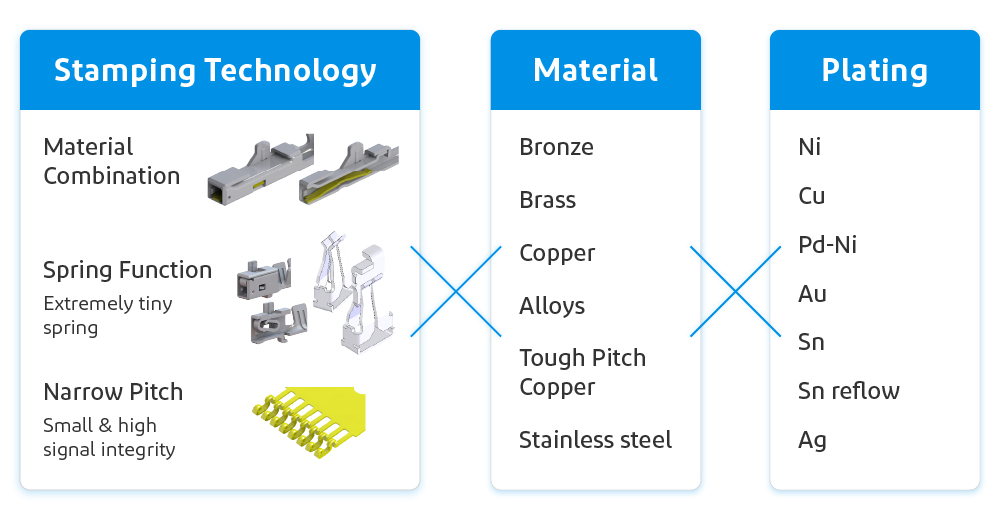

High-Precision Stamping, Material Selection, and Plating Solutions

Our company specializes in cutting-edge stamping technology and various materials and plating options. This ensures that our products are both durable and high-performing across multiple applications. By providing a variety of material and plating combinations, we effectively meet the specific needs of different industries, ranging from electronics to automotive.

Stamping Technology

- Material Combination: Utilizing a combination of high-performance materials to deliver robust, reliable stamped parts.

- Spring Function: Engineering extremely tiny springs for enhanced flexibility and durability.

- Narrow Pitch: Producing small, high-signal integrity parts optimized for modern electronic applications.

Material Options

- Bronze

- Brass

- Copper

- Alloys

- Tough Pitch Copper

- Stainless Steel

Plating Options

- Nickel (Ni)

- Copper (Cu)

- Palladium-Nickel (Pd-Ni)

- Gold (Au)

- Tin (Sn)

- Tin Reflow

- Silver (Ag)