I-PEX Inc. (Headquarters: Kyoto City, Kyoto Prefecture, Representative Director and President: Reiji Konishi, hereinafter referred to as I-PEX) will start accepting orders for engineering samples of the human-detection safety sensor “Smart Cloth” (hereinafter referred to as Smart Cloth), which has been under development since 2024*and is ideal for collaborative robots and other applications, from December 2025.

Smart Cloth is a new concept sensor that combines safety and flexible applicability, by using a unique conductive fabric technology to detect objects approaching within 15 cm before they make contact with a person.

Smart Cloth will be exhibited at the 2025 International Robot Exhibition held at Tokyo Big Sight from December 3rd to 6th, 2025.

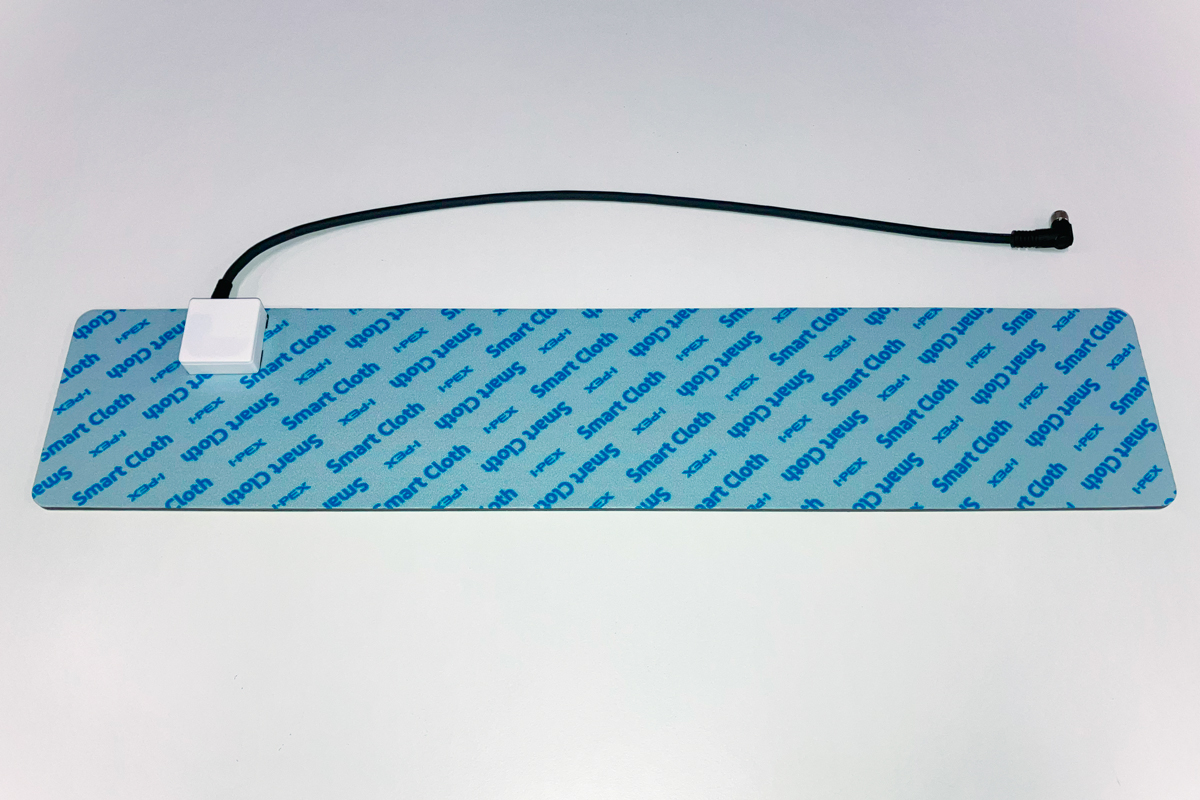

Human-detection safety sensor, Smart Cloth (engineering sample)

Human-detection safety sensor, Smart Cloth (engineering sample)

Background to the Development of Smart Cloth

I-PEX has previously offered the ESTORQ®, a solution using Electrostatic Capacitance Torque Sensor, to instantly stop a robot upon contact with a person. However, robot manufacturers have requested a solution that stops robots before contact occurs, and the lack of a versatile proximity sensor on the market has been an issue.

I-PEX therefore focused on conductive fabric, which combines the flexibility of cloth with the conductive properties of other materials, and developed Smart Cloth, which can be used in a variety of robots.

Features of Smart Cloth

Smart Cloth is a proximity sensor made of conductive fabric that detects objects up to 15 cm away without contact. Its cloth-based structure offers flexibility, making it easy to fit workpieces of various shapes or areas where there is a risk of contact with people, such as robots.

- The contactless technology detects proximity up to 15cm before a person comes into contact with the device.

- The flexibility of the fabric allows for easy installation by attaching or wrapping the product around the target area.

- Smart Cloth can be used for a wide range of applications, including industrial robots, AMR/AGVs, machine tools, and service robots

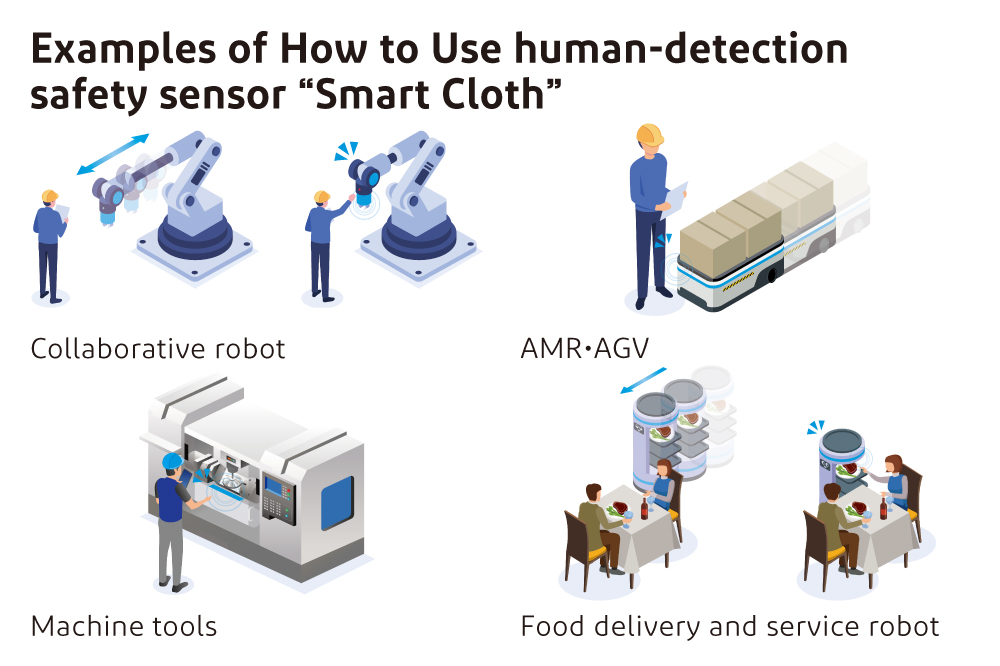

Examples of How to Use Smart Cloth

Image of the use of the human-detection safety sensor Smart Cloth

Image of the use of the human-detection safety sensor Smart Cloth

By installing Smart Cloth in the following locations, it can be used to avoid contact and as a safety aid.

- Collaborative robot end effector

- Door parts of machine tools, semi-automatic machines (jigs), molding machines, etc.

- AMR/AGV housing

- Food delivery and service robot housing

In addition to the above, Smart Cloth is anticipated to be used in a wide range of applications, including amusement games, housing facilities, construction and building maintenance, nursing care equipment, medical equipment, shutters, and as a general-purpose sensor.

Smart Cloth Product Specifications

| Product name | human-detection safety sensor Smart Cloth |

|---|---|

| Detection distance | Up to approximately 15cm |

| External dimensions | 120mm × 600mm |

| Weight | Approximately 100g |

| Output | Non-voltage contact |

| Power supply | DC 24V |

| Protection class | IP20 |

| Operating temperature and humidity range | 0 to 50°C/0 to 95% (no condensation) |

| Certifications | Safety2.0 |

- *This product is an engineering sample and specifications may change without notice.

Download Catalogue

- 「Smart Cloth」 製品カタログ(2.7MB)

- HCI Co., Ltd. Booth No. W1-14

- YANAGIHARA MECHAX CO., LTD. Booth No. W1-50

Exhibiting at the International Robot Exhibition 2025

I-PEX will exhibit Smart Cloth at the 2025 International Robot Exhibition to be held at Tokyo Big Sight from Wednesday, December 3rd to Saturday, December 6th, 2025.

| Dates | Wednesday, December 3rd – Saturday, December 6th, 2025 |

|---|---|

| Place | Tokyo Big Sight |

| Exhibition Booth | |

| Exhibit Products | Smart Cloth |

About I-PEX Sensor Products

I-PEX has developed its own sensing technology and offers a diverse range of sensors that enhance collaboration and safety, including ESTORQ®series of torque sensors for human-robot contact detection, Smart Cloth for non-contact proximity sensing and smell sensors such as nose@MEMS® and noseStick® powered by MEMS technology. I-PEX is creating unprecedented solutions that contribute to safety and comfort in a wide range of applications, from industrial to lifestyle and mobility.

About I-PEX Inc.

I-PEX stands for “Innovative Product development & Engineering solutions eXpert” providing value in the form of inspiration and astonishment in the global marketplace. The company was founded in 1963 as Dai-ichi Seiko, a precision mold manufacturer, and has since produced numerous world-firsts and unique products and solutions. I-PEX currently operates in five business fields: Connectors, Contract Manufacturing (Automotive Components & Electronics Components), Molds & Equipment, MEMS Foundry, and Energy Solutions. By delivering the sharpest tip to the world, we will contribute to exciting value-creation in the digitalized society by working globally with every customer who opens up the new era.

| Trade Name | I-PEX Inc. |

|---|---|

| President | Representative Director and President Reiji Konishi |

| Location | 12-4 Negoro, Momoyama-cho, Fushimi-ku, Kyoto 612-8024 |

| Establishment | July 10, 1963 |

| Paid-in Capital | 9.968 billion yen (as of November 10, 2025) |

| Business Operation | ・ Connectors Business ・ Contract Manufacturing Business (Automotive Components & Electronics Components) ・ Mold & Equipment Business ・ MEMS Foundry Business ・ Energy Solutions Business |

| URL | https://corp.i-pex.com/en |