The I-EA-T Circular Economy Pride Award Ceremony held by the Industrial Estate Authority of Thailand

The I-EA-T Circular Economy Pride Award Ceremony held by the Industrial Estate Authority of Thailand Since its establishment in 2000, I-PEX (Thailand) Co., Ltd. (I-PEX Thailand) has built a reputation for excellence in precision molded components for hard disk drives (HDDs) and automotive applications.

Going beyond its mission as an Innovative Product and Engineering solutions eXpert, I-PEX Thailand is recognized as a leader in sustainable and environmental innovation.

In November 2024, for the second consecutive year, the company was awarded the Amata Best Waste Management Award (Platinum Level) delivered by Amata Industrial Estate, where the plant is located. This achievement was followed in 2025 by the prestigious I-EA-T Circular Economy Pride Award, presented by the Industrial Estate Authority of Thailand. These recognitions reflect more than operational success—it affirms I-PEX Thailand’s commitment to building a future where precision and sustainability go hand in hand.

For more details about I-PEX (Thailand) Co., Ltd.

Driving Circular Innovation: Embracing the 3Rs (Reduce, Reuse, Recycle)

Field Audit of Hazardous Waste Disposal Sites

Field Audit of Hazardous Waste Disposal Sites Desk Audit for General Waste Management Contractors

Desk Audit for General Waste Management ContractorsAt I-PEX Thailand, sustainability is a core principle embedded in our operation methods. As a manufacturer working with resins and plastics molding, we recognize the environmental responsibility in managing the use of our materials. That’s why we’ve fully embraced the 3Rs—Reduce, Reuse, Recycle—as the foundation of our waste management strategy.

The 3R strategy starts at the source. By optimizing our production processes, we minimize material waste before it’s even created. Scraps such as runners and tray remnants are reprocessed and blended with virgin resin, allowing us to reintroduce materials into the production cycle. This not only reduces industrial waste and significantly cuts down on the need for new raw materials but also highlights our strong commitment to sustainable resource management and innovative manufacturing technology.

Our strategy does not stop at reduction and reuse. With a robust recycling program and strict oversight of waste processors, we’ve proudly maintained zero waste to landfill since 2022. Every piece of industrial waste is either reused or recycled—supporting a closed-loop system that contributes to a thriving circular economy.

Caring for Water: Advancing Water Stewardship

Production Flow and Environmental Initiatives at I-PEX (Thailand) Co., Ltd. – Chonburi Factory

Production Flow and Environmental Initiatives at I-PEX (Thailand) Co., Ltd. – Chonburi FactoryOur efforts toward water stewardship extend beyond our own facilities. We actively collaborate with stakeholders across the entire watershed to promote the sustainable management and responsible use of water resources.

We believe that responsible manufacturing means protecting one of our planet’s most vital resources—water. In Southeast Asia, a region where water scarcity and pollution are serious challenges, we are committed to doing more with less and doing it better.

Producing high-precision components such as mechanical components used in HDDs demands rigorous cleaning processes that traditionally consume large volumes of highly purified water—over 18,000 tons annually—to remove surface impurities.

In addition to this large consumption, the deionized water plant, which purifies water for these processes, generates wastewater carrying away filtered impurities.

Recognizing the environmental impact of these operations, we've taken decisive steps to reduce our water footprint.

Since 2020, we’ve implemented a water recycling system that transforms the deionized plant wastewater into clean, reusable sanitary water.

Despite early challenges—such as meeting strict water quality standards and managing high conductivity levels—we pushed forward through close collaboration with our suppliers and our team members. In 2024, we successfully reused 60% of our wastewater through our water recycling system, resulting in a 15% reduction in our total water consumption.

We will continue to pursue further innovation toward realizing a perfect circular water usage system that aims for zero wastewater.

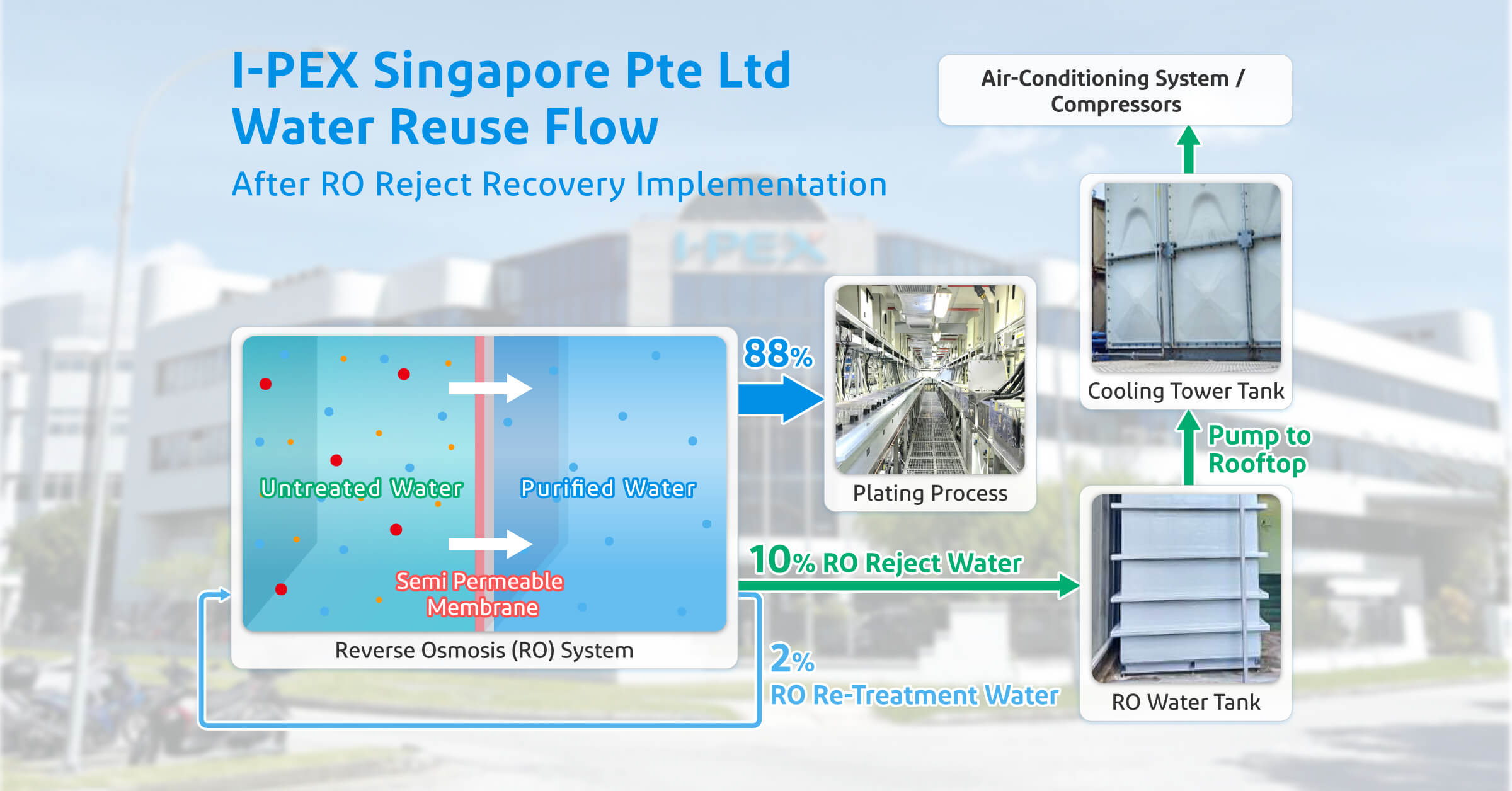

Discover how I-PEX reuses water with reverse osmosis (RO) technology

Starting with I-PEX Singapore Pte Ltd (Singapore Plant), the reuse of the RO water has become one of the sustainability initiatives throughout the I-PEX Group.

Please refer to the following article for more information on the initiatives of our Singapore Plant.

Reclaiming Factory Wastewater as a Resource: The Aquaponics Green Farm Initiative

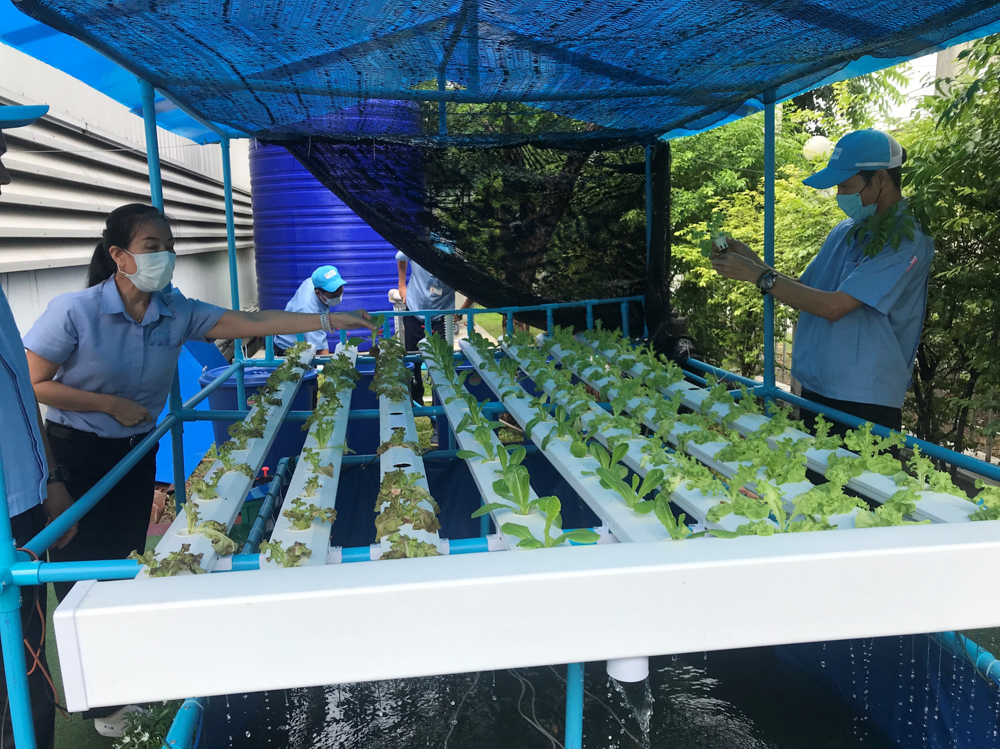

The Aquaponics Green Farm, a system to grow vegetables and fish using factory wastewater

The Aquaponics Green Farm, a system to grow vegetables and fish using factory wastewaterAt our Chonburi Plant, we believe that true sustainability means going beyond compliance. Guided by our vision of advancing our sustainable water management efforts, we keep on embracing new challenges.

A key example of this commitment is our Aquaponics Green Farm Initiative, launched in 2023.

The Aquaponics Green Farm is a circular agricultural system that reuses the final stage treated water from our production processes to produce fish and vegetables. This pioneering project reimagines wastewater not as a byproduct, but as a resource.

The harvested produce is then shared with employees, serving both as a tool for environmental education and a contribution to employees' well-being, deepening environmental awareness across our whole team.

Through this initiative, we are moving closer to our goal of 100% water recycling—and proving that sustainable manufacturing can be regenerative, innovative, and focused on enhancing the lives of our employees and community members.

Awarded the AMATA Waste Management Award (Platinum) for the Second Consecutive Year: Celebrating Excellence and Advancing Innovation

Amata Best Waste Management Award Ceremony

Amata Best Waste Management Award CeremonyOur efforts to improve water efficiency and environmental initiatives of our Chonburi Plant have been highly evaluated in Thailand.

For two consecutive years, in 2023 and 2024, we were honored with the Amata Best Waste Management Award (Platinum Level), presented by the AMATA Industrial Estate where the plant is located. In 2025, we also proudly received the I-EA-T Circular Pride Award from the Industrial Estate Authority of Thailand.

The above awards recognize companies that demonstrate excellence in industrial waste management, environmental awareness, and the promotion of sustainable business practices. These achievements reflect our pride in being an environmentally advanced company that grows together with the local community.

At our Chonburi Plant, sustainability is not just a goal, it’s a responsibility.

Looking ahead, we will accelerate our efforts to increase the use of recycled materials and develop new technologies, striving to deliver environmentally conscious manufacturing that generates lasting value. Together with our stakeholders, we will aim to build a future that is both stronger and more sustainable.