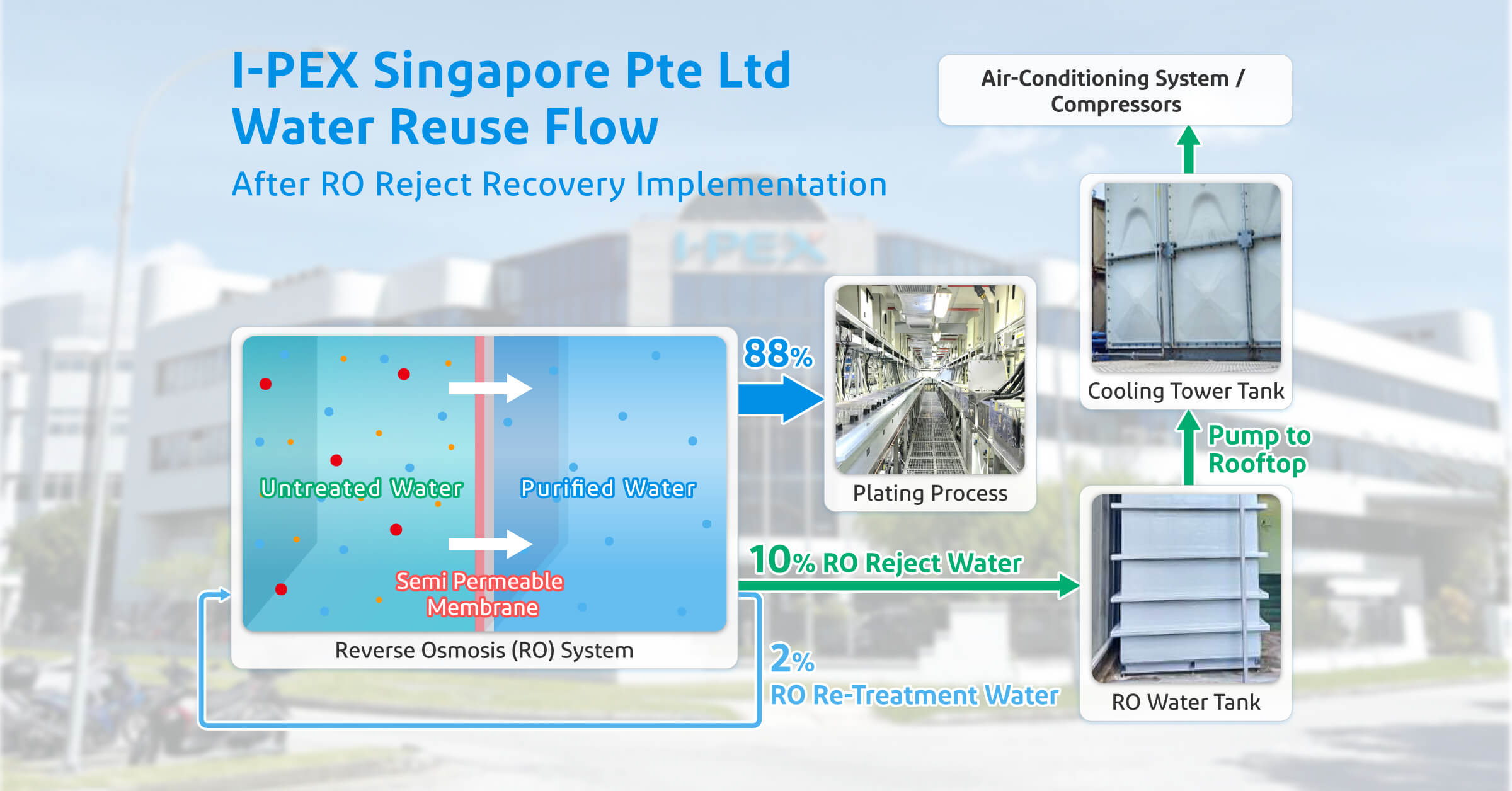

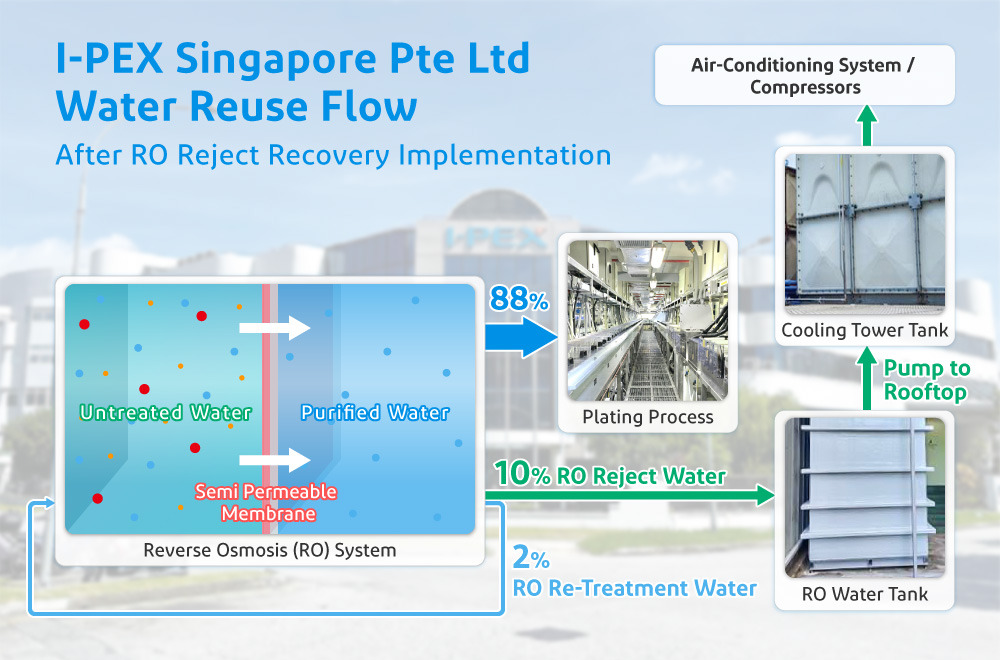

I-PEX Singapore Pte Ltd Water Reuse Flow: After RO Reject Recovery Implementation

I-PEX Singapore Pte Ltd Water Reuse Flow: After RO Reject Recovery ImplementationIn a world where water scarcity is becoming an ever-pressing issue, every drop counts. Singapore, renowned for its innovative water management, faces significant challenges due to its limited natural water resources.

Amidst this backdrop, I-PEX Singapore Pte Ltd has embarked on a groundbreaking journey to turn wastewater into a valuable resource, showcasing their commitment to sustainability and environmental stewardship.

Driven by its vision of being “people-friendly and Earth-friendly,” the I-PEX Group is committed to reducing its environmental impact. At the heart of this mission is the Yishun Plant, where an innovative solution has been developed to transform wastewater into a resource that not only conserves water but also supports the plant's operations.

Key Outcomes of the Project:

- 5,679 tons of water reused (in 2023)

- 29% reduction in annual water consumption

- Recognized by PUB (Singapore Water Agency) and featured on national media

I-PEX Singapore Pte Ltd: A Key Player in Connector Production Amid a Water Crisis

Yishun Plant, I-PEX Singapore Pte Ltd

Yishun Plant, I-PEX Singapore Pte LtdSince its opening in 1993, the Yishun Plant of Singapore Dai-ichi Pte. Ltd. (currently I-PEX Singapore Pte Ltd*) has been one of our hubs of integrated connector production. The plant houses departments for mold manufacturing, injection, press, plating, assembly, quality assurance, and shipping.

Notably, the plant is one of our four sites with a plating line, a crucial process in connector manufacturing that consumes about 100 tons of water daily.

Yishun Plant is located in the Northern region of Singapore, a country known for facing significant challenges due to its limited natural water resources and restricted land for water storage, making it one of the most water-stressed countries.

Over the past decades, Singapore has become a global leader in water management, continuously innovating to meet the needs of its population and growing economy.

- ﹡I-PEX Inc. changed its name from Dai-ichi Seiko Co., Ltd. in 2020. Each Group company changes its corporate name accordingly.

Precision Needs Water: Why Innovation is Crucial for a Sustainable Plating Process

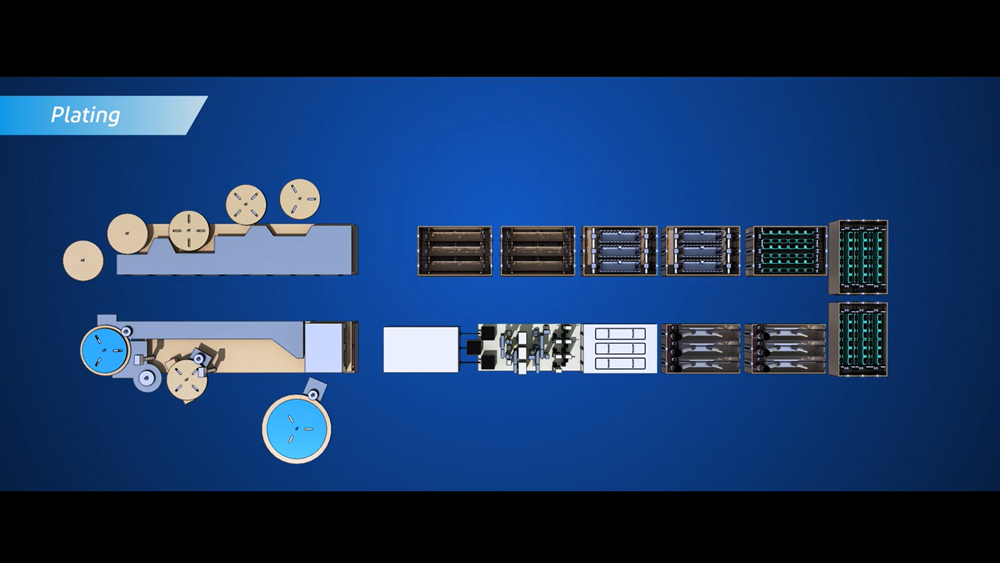

Plating involves coating the surface of stamped metal parts of the connector with a thin layer of metal, typically nickel and gold. This enhances the connectivity and prevents the products from rusting.

During plating, the metal parts of the connectors pass through various tanks filled with water and chemicals. These tanks serve different purposes, such as cleaning the parts by removing debris and oil, and applying the underlying and finishing plating layers.

Plating line at the Yishun Plant

Plating line at the Yishun Plant Plating process tanks: from the left to right, the various processing tanks using water and chemicals as part of the plating process.

Plating process tanks: from the left to right, the various processing tanks using water and chemicals as part of the plating process. For more information on connectors manufacturing process: Virtual Plant Tour

The plating process consumes a significant amount of water, approximately 100 tons per day. To conserve water and minimize environmental impact, the water used in plating is treated with a reverse osmosis system.

This system pressurizes the used water and filters it through a microscopically small membrane, producing pure water that can be reused in the plating process.

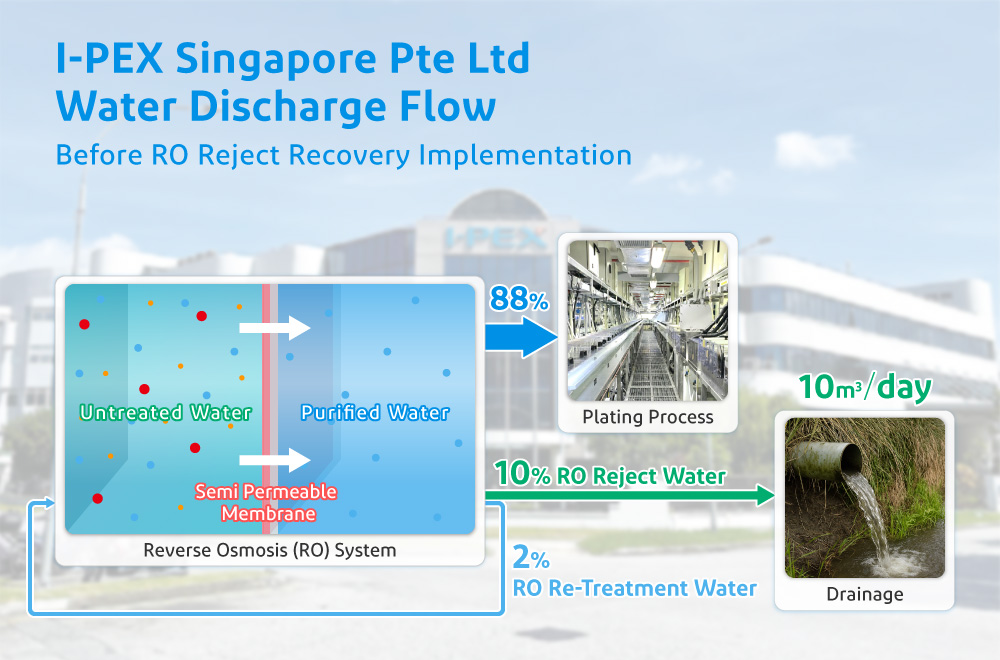

However, the reverse osmosis process also generates wastewater, which carries away the filtered impurities. Although this wastewater cannot be used in the plating process, it contains far fewer impurities than domestic wastewater. It is treated at the factory before being discharged into the sewage system.

At the Yishun Plant, 10 tons of wastewater are discharged daily, a significant amount in a country where water saving is a national issue.

Transforming Wastewater into a Valuable Resource: A Sustainability Leap Earns Recognition from the Government of Singapore

I-PEX Singapore Pte Ltd Water Discharge Flow: Before RO Reject Recovery Implementation

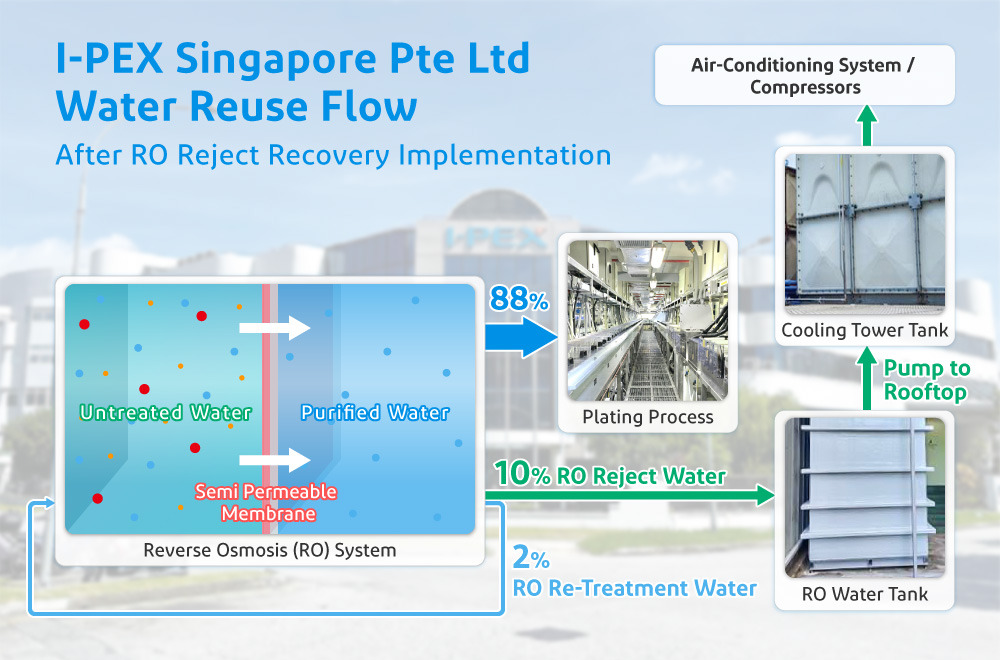

I-PEX Singapore Pte Ltd Water Discharge Flow: Before RO Reject Recovery ImplementationIn February 2022, the Yishun Plant’s plating department began exploring ways to reuse the 10 tons of water discharged daily. After several suitability surveys, it was determined that the wastewater from the reverse osmosis process could be used as cooling water for the plant’s air conditioning and air compressors.

This project was challenging as it required upgrading the plant’s infrastructure to improve the plumbing system. The recycling process started operating in April 2023. The wastewater is now stored in a tank before being sent to the cooling tower on the plant’s rooftop, where it is used in the facility’s cooling system.

This project, which reuses water that would otherwise be discharged, has been recognized for its contribution to addressing Singapore’s water shortage. I-PEX Singapore Pte Ltd received an incentive from the PUB (Singapore’s National Water Agency) Water Efficiency Fund which encourages organizations to improve their water efficiency.

I-PEX Singapore Pte Ltd Water Reuse Flow: After RO Reject Recovery Implementation

I-PEX Singapore Pte Ltd Water Reuse Flow: After RO Reject Recovery Implementation

In addition to reducing water bills, this project allows the Yishun Plant to reuse 5,679 tons of wastewater, a 29% reduction in annual water consumption for 2023.

This effort has been highlighted in Singapore business magazines and on TV as a sustainability initiative.

Interview of Mr. Joseph Choo, project leader, for Channel News Asia (a Singapore-based multinational news channel) on September 27, 2023: Firms take steps to use less water ahead of price hikes

Interview of Mr. Joseph Choo, project leader, for Channel News Asia (a Singapore-based multinational news channel) on September 27, 2023: Firms take steps to use less water ahead of price hikesFirms take steps to use less water ahead of price hikes (Channel News Asia)

Following the recognition from PUB, this project was also awarded the I-PEX Corporate Identity Prize, highlighting the innovative spirit and the dedication of the I-PEX Singapore team. Their hard work is a testament to what can be achieved when we prioritize sustainability, and the details of their installation was widely shared among our Group as an example.

A Vision for the Future: Driving Global Sustainability Through Innovation in Manufacturing

This initiative not only addresses Singapore’s water shortage but also sets a precedent for sustainable practices in industrial operations, particularly in the field of sustainable manufacturing. By reusing water that would otherwise be wasted, I-PEX Singapore Pte Ltd is paving the way for a more sustainable future, demonstrating that innovative water reuse solutions can lead to significant environmental benefits.

Looking into the future, the I-PEX Group remains committed to supporting local and global sustainability initiatives that contribute to the realization of a sustainable society. This project serves as a beacon of hope and a model for other manufacturing organizations aiming to implement industrial water recycling and green factory practices. Together, we can make a difference and ensure a better, more sustainable world for generations to come.

Overview of I-PEX Singapore Pte Ltd

| Company Name |

I-PEX Singapore Pte Ltd

|

|---|---|

| Location |

55 Yishun Industrial Park A, Singapore 768728

|

| Number of Employees |

269 (as of February 28, 2025)

|

| Business Contents |

Manufacture of Connectors

|