I-PEX Inc. (Headquarters: Kyoto City, Kyoto Prefecture, Representative Director and President: Reiji Konishi, hereinafter I-PEX) and URUTAMA Inc. (Headquarters: Kawasaki City, Kanagawa Prefecture, CEO: Emiko Saito, hereinafter URUTAMA) have conducted flight tests of a micro drone using two types of battery packs equipped with the advanced conductive mesh currently being developed by I-PEX, and have achieved a flight time of over 16 minutes with both battery packs, which is approximately double that of existing battery packs of the same weight.

The advanced conductive mesh is a current collector that contributes to enhancing next-generation lithium-ion battery performance by improving the adhesion and conductivity of silicon-based active materials.

Actual samples of this technology and technical explanation materials will be exhibited at the I-PEX booth (6F No. 15) at the 66th Battery Symposium Co-exhibition, to be held at Winc Aichi in Aichi Prefecture from Tuesday, November 18th to Thursday, November 20th, 2025.

Based on these results, I-PEX will collaborate with URUTAMA to verify the cycle characteristics, safety, and mass production of batteries equipped with the advanced conductive mesh, and will continue development toward future product integration.

Micro drones using battery packs equipped with advanced conductive mesh achieve flight times of over 16 minutes

Micro drones using battery packs equipped with advanced conductive mesh achieve flight times of over 16 minutes

Flight Test Background

In recent years, there has been a growing need to use micro drones to visually inspect and check dangerous locations that are difficult to see with the human eye, such as nuclear power plants and road collapse sites.

The micro drones used for these purposes have a limited battery capacity due to weight restrictions. Currently, they can only fly for a maximum of about 8 minutes at a time, including the time it takes to travel to and from the site, which means that actual inspections can only be carried out for a few minutes.

I-PEX's advanced conductive mesh is being developed as a current collector to improve the performance of next-generation lithium-ion batteries, utilizing silicon-based active materials that have a theoretical capacity more than 10 times that of graphite-based active materials. *1 A flight test was conducted using a micro drone to demonstrate the improved performance of a battery pack equipped with the advanced conductive mesh.

Flight Test Overview

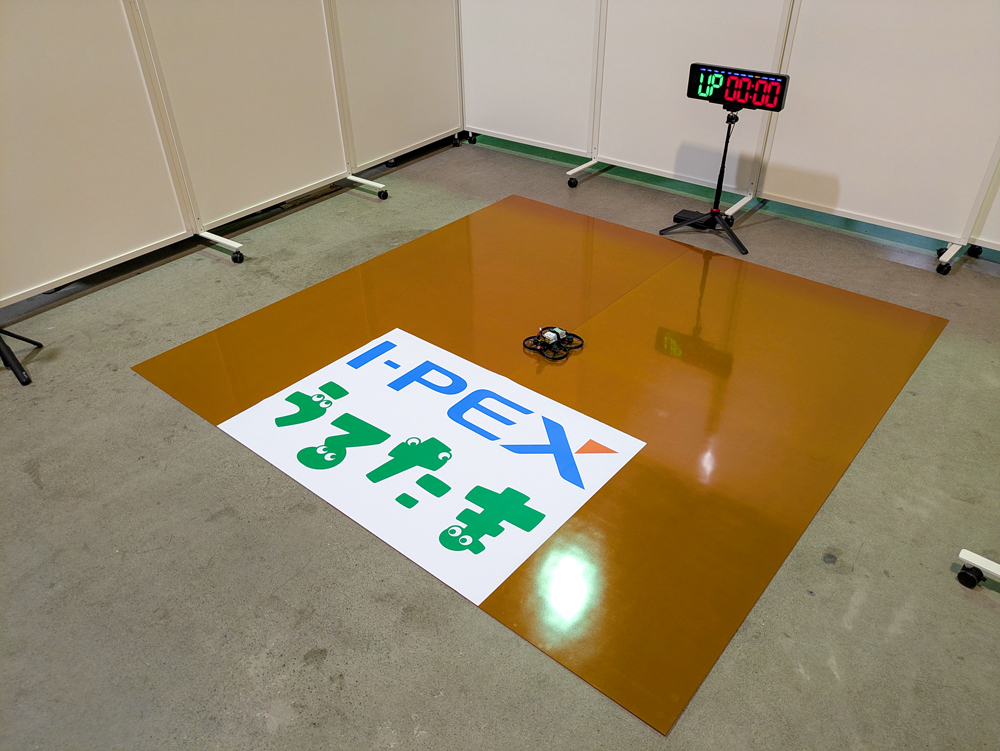

Flight Test Area

Flight Test Area

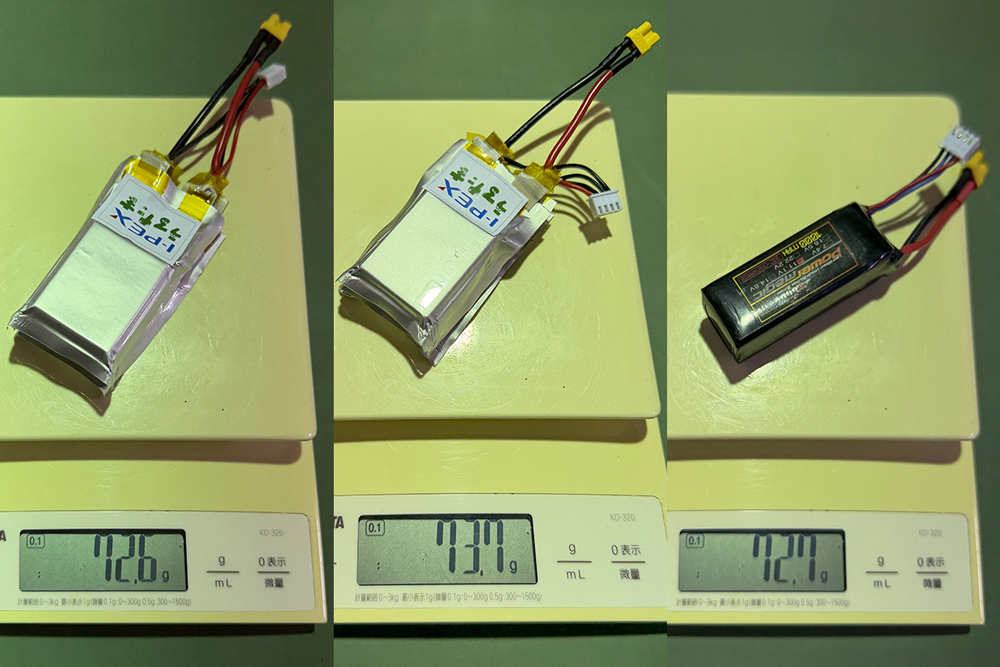

URUTAMA produced two types of battery packs using I-PEX's advanced conductive mesh, mounted them on a micro drone, and conducted a hovering flight test at URUTAMA's lab (Leading Venture Plaza, Tsurumi-ku, Yokohama) after matching the weight as closely as possible to a commercially available battery pack for comparison.

As for the test result, the aircraft hovered for 8 minutes and 51 seconds using a commercially available battery pack, 16 minutes and 20 seconds using the silicon anode battery pack, and 17 minutes and 42 seconds using the lithium anode battery pack, nearly doubling the flight time over the commercial option.

Details of the installed battery pack and test results

| Battery pack | Silicon anode battery pack *2 | Lithium anode battery pack *3 | (For comparison) Commercially available battery pack |

|---|---|---|---|

| Number of cells | 3 | 3 | 3 |

| Capacity | 1800mAh | 1930mAh | 1000mAh |

| Voltage | 11.1V | 12.0V | 11.1V |

| Weight | 72.6g | 73.7g | 72.7g |

| Flight Time | 16 minutes and 20 seconds | 17 minutes and 42 seconds | 8 minutes and 51 seconds |

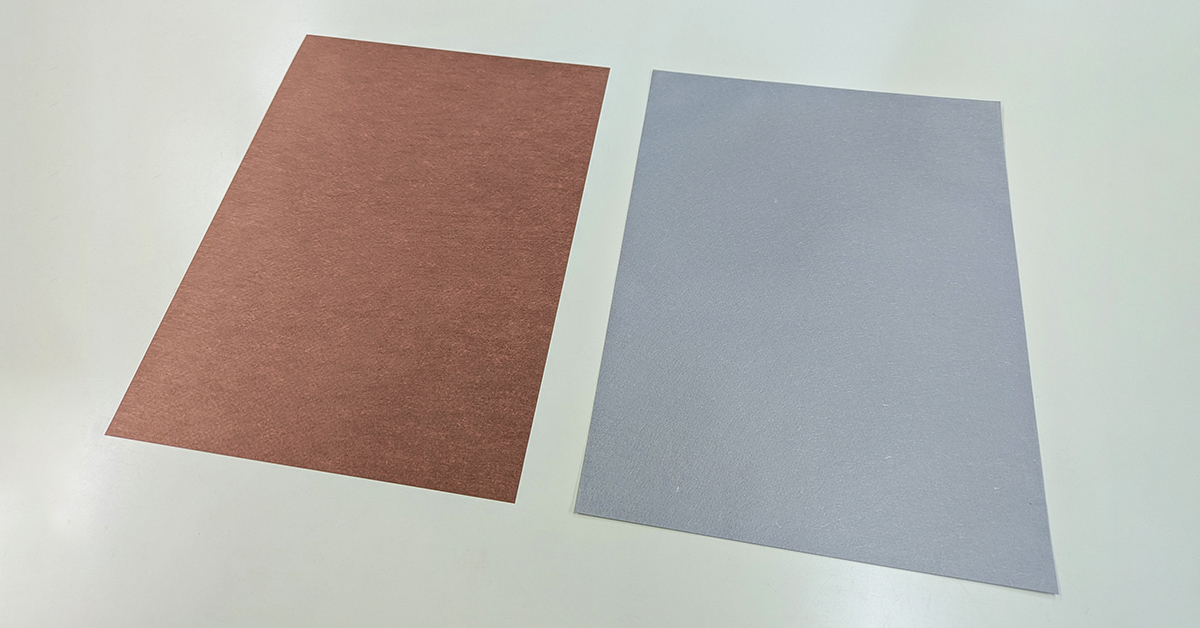

- *2A copper-plated advanced conductive mesh is used, and the active material (Si/graphite ≒ 83%/17%, micro-Si is used) is coated and embedded in the voids of the nonwoven fabric.

- *3The world's lightest three-dimensional lithium metal anode was created by embedding Li in a copper-plated advanced conductive mesh

Battery packs installed in micro drones (left: silicon anode battery pack, center: lithium anode battery pack, right: commercially available battery pack for comparison)

Battery packs installed in micro drones (left: silicon anode battery pack, center: lithium anode battery pack, right: commercially available battery pack for comparison)

Micro drone used in flight tests

Micro drone used in flight tests

Features of the Advanced Conductive Mesh

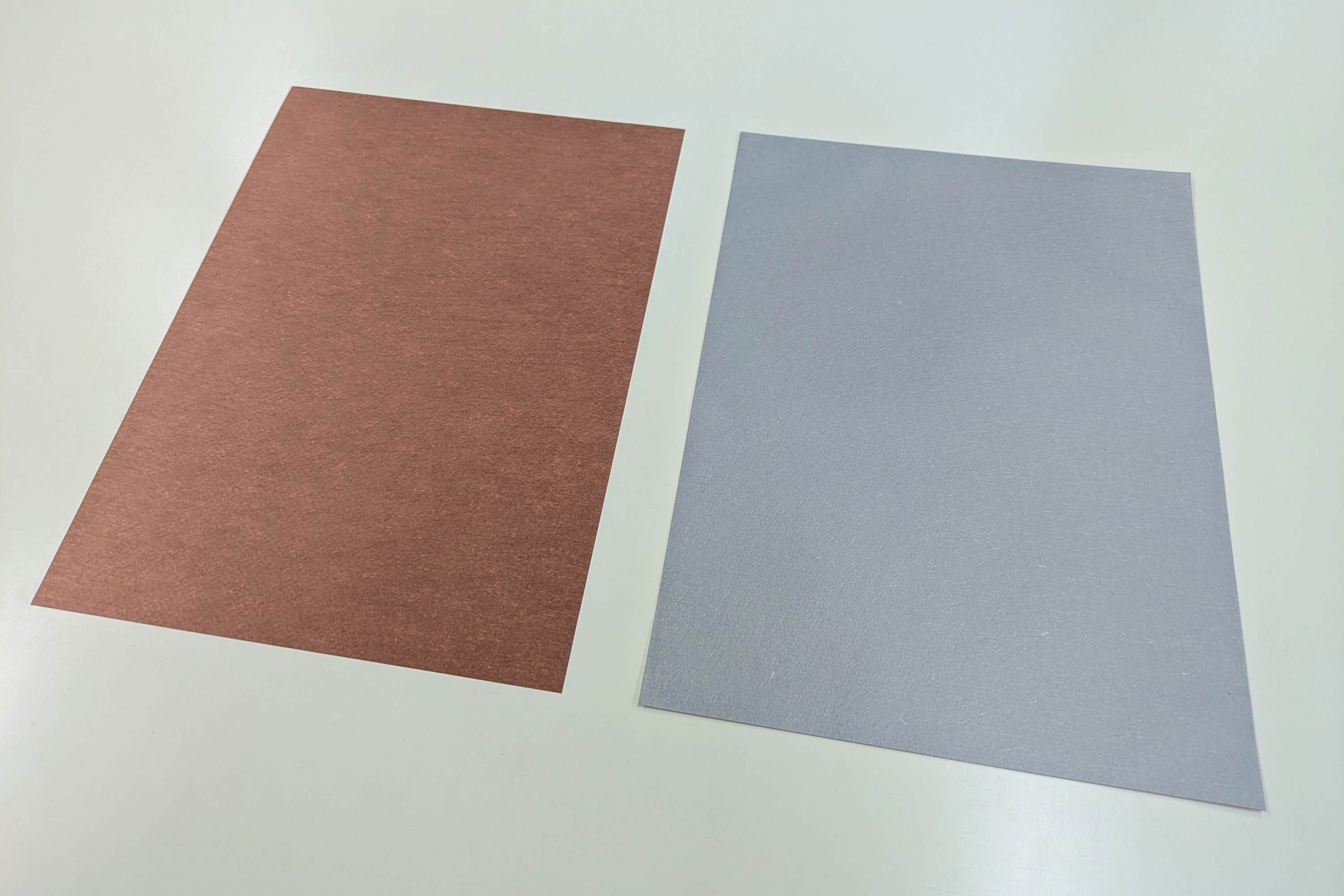

Advanced conductive mesh (Left: copper-metallized product, Right: aluminum-metallized product)

Advanced conductive mesh (Left: copper-metallized product, Right: aluminum-metallized product)

The advanced conductive mesh is expected to improve issues such as the adhesion and conductivity of silicon-based active materials in next-generation lithium-ion batteries, thereby contributing to improved battery performance.

- The complex and flexible structure of the nonwoven fabric holds the active material in place, preventing peeling caused by the expansion and contraction of the silicon-based active material

- Metallization of nonwoven fabric ensures a high specific surface area of the current collector and electrical conductivity comparable to that of copper foil

- The conductive nonwoven fabric forms a conductive path throughout the active material layer, improving the utilization rate of the active material

- The current collector is made lighter by using a resin nonwoven fabric as the base material

For more information on the advanced conductive mesh please click here.

Exhibition Overview

The advanced conductive mesh will be exhibited at the "66th Battery Symposium Exhibition" to be held at Winc Aichi from Tuesday, November 18th to Thursday, November 20th, 2025.

| Dates | November 18th (Tuesday) - 20th (Thursday), 2025 |

|---|---|

| Place | Winc Aichi (Nakamura Ward, Nagoya City) |

| Exhibit Products | Advanced conductive mesh |

About URUTAMA Inc.

URUTAMA Inc. is conducting research and development that will lead to the commercialization of next-generation batteries by discovering "original elemental technologies" that will solve the various technical barriers in the secondary battery development and manufacturing process. Furthermore, based on the experience gained in this research process, we are already conducting joint research and contract research on battery technology with many affiliated companies.

- Connectors Business

- Contract Manufacturing Business (Automotive Components & Electronics Components)

- Mold & Equipment Business

- MEMS Foundry Business

- Energy Solutions Business

| Trade Name | URUTAMA Inc. |

|---|---|

| President | Representative Director: Emiko Saito |

| Location | Kawasaki Frontier Building 4th floor, 11-2 Ekimae Honmachi, Kawasaki-ku, Kawasaki City, Kanagawa Prefecture |

| Business Operation | Next-generation battery development and contract evaluation business |

About I-PEX's Energy Solutions Business

I-PEX has developed the "RENERATH" series of storage battery systems, which reuse used lithium-ion battery packs from electric vehicles. By combining reused battery packs with IoT technology, the company aims to provide a sustainable, safe, and secure energy supply through storage batteries. As a new initiative in energy solutions, the company is currently developing advanced conductive mesh for next-generation lithium-ion battery packs.

About I-PEX Inc.

I-PEX stands for “Innovative Product development & Engineering solutions eXpert” providing value in the form of inspiration and astonishment in the global marketplace. The company was founded in 1963 as Dai-ichi Seiko, a precision mold manufacturer, and has since produced numerous world-firsts and unique products and solutions.

I-PEX currently operates in five business fields: Connectors, Contract Manufacturing (Automotive Components & Electronics Components), Molds & Equipment, MEMS Foundry, and Energy Solutions. By delivering the sharpest tip to the world, we will contribute to exciting value-creation in the digitalized society by working globally with every customer who opens up the new era.

| Trade Name | I-PEX Inc. |

|---|---|

| President | Representative Director and President Reiji Konishi |

| Location | 12-4, Negoro, Momoyama-cho, Fushimi-ku, Kyoto 612-8024, JAPAN |

| Establishment | July 10, 1963 |

| Paid-in Capital | 9.968 billion yen (as of November 10, 2025) |

| Business Operation |

|

| URL | https://corp.i-pex.com/en |