I-PEX develops unique new businesses at each of its global locations, leveraging the characteristics of each region.

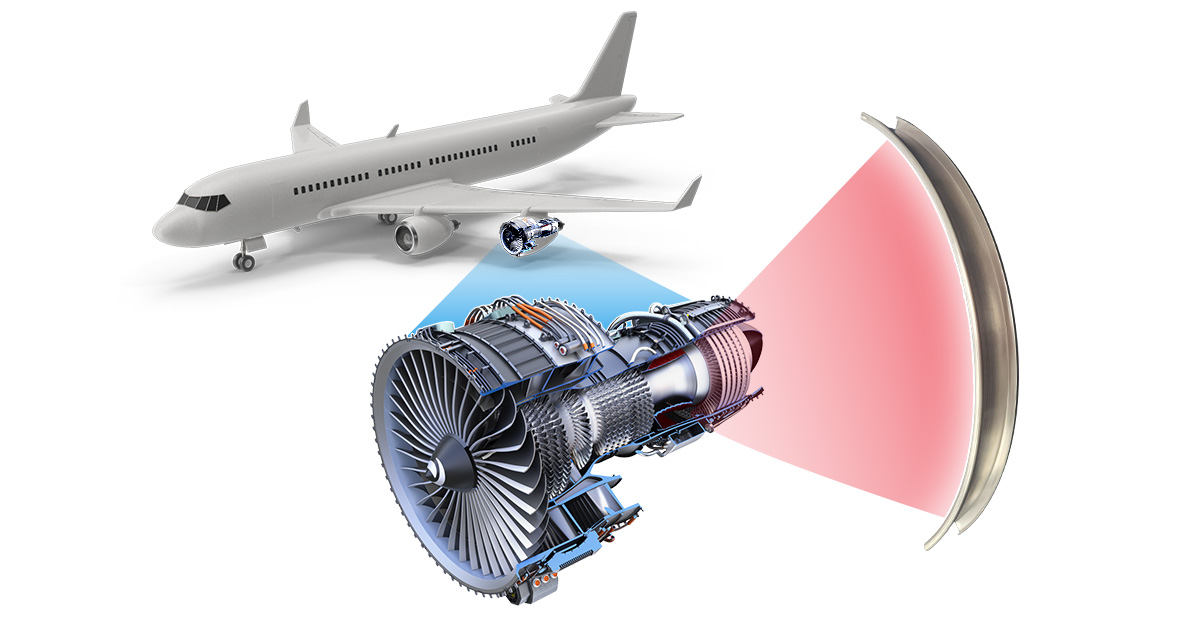

One of these initiatives is the aerospace component business centered in Singapore. From this hub, one of Asia’s leading aviation centers, we began supplying turbine shrouds for aircraft engines to the OEM and MRO markets in 2024. As a first step into this new challenge, we are applying the technologies cultivated in precision connectors to the aerospace sector. This marks a new endeavor to adapt I-PEX’s precision manufacturing capabilities to the highly demanding standards of the aircraft industry.

Supplying Turbine Shrouds that Meet Stringent Requirements

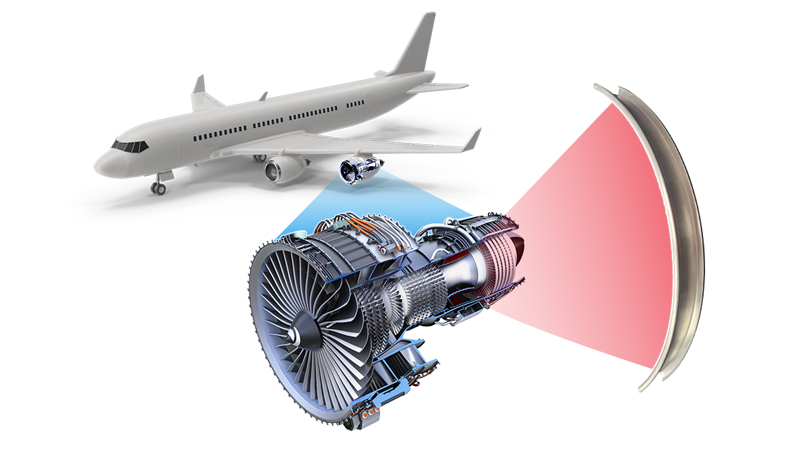

Turbine Shroud

Turbine ShroudA turbine shroud is a component that surrounds the outer circumference of turbine blades inside an aircraft engine. It prevents combustion gas leakage while ensuring the stability of the blades. The shroud plays a critical role in determining both the efficiency and durability of the engine, yet it must operate in an extremely high-temperature, high-pressure environment. Meeting international aerospace standards requires exceptional levels of precision and reliability.

I-PEX leverages its expertise in quality control and precision machining, cultivated in the electronics field, to supply products that meet these demanding requirements.

In manufacturing, a honeycomb structure is first positioned and secured during the assembly process. It is then permanently bonded to the shroud through a brazing process.

By combining two short shrouds and two long shrouds, a complete 360-degree ring structure is formed. The honeycomb functions as a sacrificial layer, absorbing wear and easing strict tolerance requirements during assembly, while also ensuring long-term durability.

Unique Roll Forming Technology

Roll Forming Machine

Roll Forming MachineSupporting I-PEX’s turbine shrouds is our uniquely refined roll forming technology. Roll forming is a process in which coiled metal passes continuously through rollers to form a desired profile, enabling efficient production of uniform, high-strength components.

In conventional industry practice, forming and bending are handled as separate steps. I-PEX has introduced a proprietary process that integrates forming and bending into a single operation, greatly reducing processing time, minimizing step-to-step variation, and ensuring stable quality. As a result, we have established a system capable of supplying high-precision parts with shorter lead times.

On the design side, we apply the “flower diagram” approach, which visualizes how a metal strip gradually transforms in shape as it passes through each roll station. By simulating intermediate cross-sections in detail, engineers can optimize material flow, prevent defects, and ensure consistent forming. This integration of design and manufacturing allows us to supply precision components that meet the strict standards of the aerospace industry on a stable basis.

With I-PEX’s roll forming technology, we simultaneously achieve the precision, efficiency, and reliability demanded by the aerospace sector, delivering products that meet the industry’s toughest quality requirements.

Future Outlook and Value to Customers

In addition to turbine shrouds, I-PEX also designs and manufactures jigs and fixtures essential for both production and maintenance. Aerospace components must undergo multiple processing steps to meet specifications, and jigs or fixtures are indispensable at each stage. Demand is high in both OEM and MRO markets, and further expansion is expected in this area. Looking ahead, we are also exploring entry into high-value-added fields such as aerospace machining components.

This initiative, launched in Singapore, is one of many new business efforts driven by I-PEX worldwide. By working closely with local industry and talent while delivering products and technologies that meet global standards, we will continue to contribute to the success of our customers.