Environmental Initiatives

Tackling Climate Change

The factor in the I-PEX Group’s operations that has the greatest impact on climate change linked to global warming is the CO2 associated with the purchased electricity the Group uses. We are therefore pursuing initiatives such as saving energy in production and expanding our use of renewable energy.

Energy-Saving Initiatives

The I-PEX Group promotes energy-saving in production by improving energy efficiency through capital investment, replacing current equipment with more efficient equipment, and thoroughly reducing waste and energy loss in its operations and facilities. To promote energy conservation within our Group, we have set the reduction of our electricity consumption as one of the goals of our environmental management system (ISO 14001) certification activities. We are also working to raise environmental awareness among our employees by establishing a system for sharing improvement activities and energy-saving know-how, and we are using MES to visualize the power consumption of our production facilities.

Introduction of renewable and green energy

The I-PEX Group promotes the installation of solar power equipment on the rooftop of newly constructed and existing factories, after confirming the load-bearing capacity, or unused parts of the premises, whenever possible. For existing factories where the installation of solar panels was not possible due to the roof load-bearing capacity, we will continue to consider the installation of solar power generation equipment by keeping up with the development on new technologies regarding renewable energy. We will continue to convert to green energy for our electricity consumption by selecting the most optimal locations for the installation of renewable energy equipment while monitoring market price trends.

Contributing to an Energy-Saving and a Recycling-Based Society

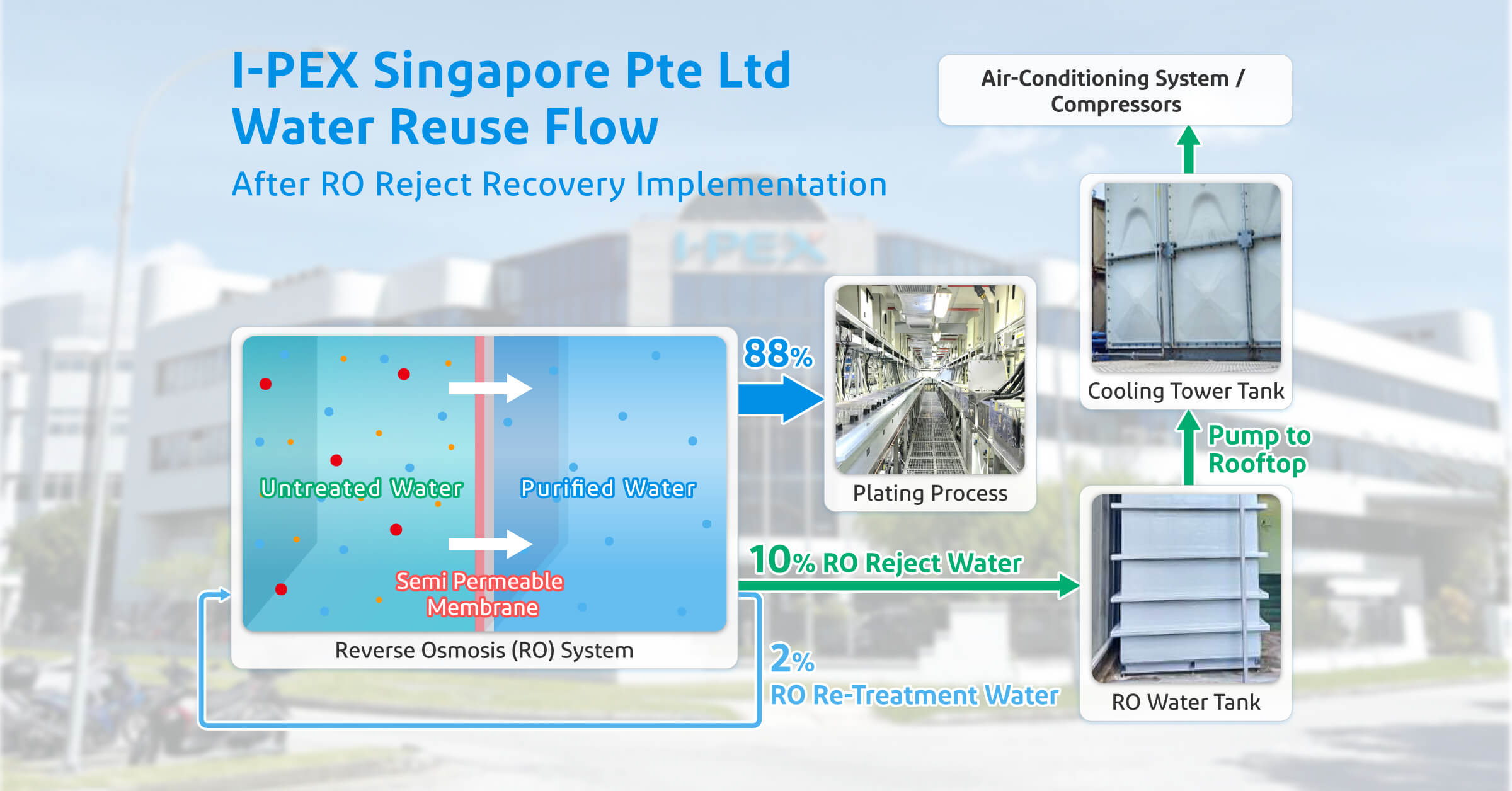

We are working to reduce our environmental impact by reducing waste through increased production efficiency and the use of recycled materials, reusing water from plating processes, and promoting the recycling of waste materials given off by business activities. We are currently conducting joint development with a mold material manufacturer to establish a sustainable lifecycle for mold materials, and going forward, we will actively promote activities to further contribute to a recycling-based society.

Action Chronology for EHS Abolition & Reduction

| Early 2004 | Started customer support service activities for RoHS Compliance. |

|---|---|

| Early 2005 | Started product developments for “lead-free” plated products beginning with customer requirement products. |

| May, 2005 | Established EHS management system. |

| June, 2006 | Started product shipments with “RoHS compliant” marking exhibit. |

| July, 2006 | All the shipment goods became “lead-free” plated products. |

| March, 2007 | Started product shipments with packing recycle marking required in “China RoHS.” |

| End of 2007 | Started REACH activities to cope with its requirements. |

| March, 2008 | Started product developments to comply with market requirement of “halogen-free.” |

| April, 2009 | Started product developments to comply with market requirement as for “Red phosphorus-free.” |

| February, 2016 | Started an investigation as 4 phthalates were added to the list of restricted substances on RoHS directive (effective from 22 July 2019). |

Environmental Initiatives

Environmental Initiatives

-

The Challenge of a Sustainable Manufacturing Strategy: Circular Innovation at I-PEX (Thailand) Co., Ltd (Chonburi Plant)

- I-PEX (Thailand) Co., Ltd.

- I-PEX Group Network

- Sustainability Activity

- Environmental Initiatives

- Social Initiatives

-

I-PEX Inc. Commits to the Science Based Targets initiative

- Sustainability News

- Corporate

- Environmental Initiatives

-

Transform Wastewater into a Resource: I-PEX Singapore’s Sustainability Innovation Project

- I-PEX Singapore Pte Ltd

- I-PEX Group Network

- Sustainability Activity

- Environmental Initiatives

- Social Initiatives

-

Donation of RENERATH Solar Street Lamp to Azumano Elementary School, Ogori City—Contributing to Disaster Prevention Measures at Designated Evacuation Shelters and Sustainable Energy Use

- Press Release

- Corporate

- Battery Storage System

- I-PEX Solutions

- Sustainability News

- Sustainability Activity

- Social Initiatives

- Environmental Initiatives