Molds/Automation System

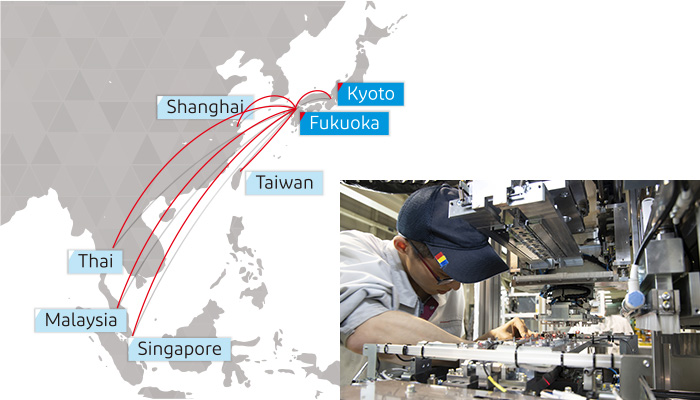

Manufacturing solution expert, I-PEX, which successfully produces various kinds of molds and automatic machines, happily supports customers.

Based on the precision processing technologies of I-PEX, we support customers in establishing facility solutions for innovation. Our mass production technology solves customers' problems by using efficient precision molds and automation systems and contributes significantly to production stability.

Strengths and features

List of Solutions

-

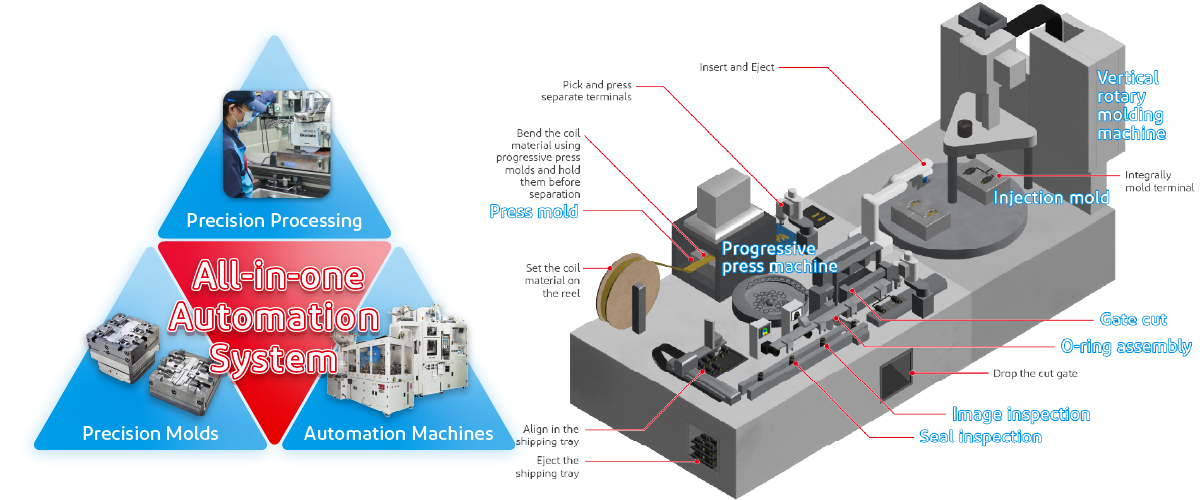

All-in-one system including molds and automatic machines

Your production will be fully automated with a single piece of equipment by aggregating precision molding molds and precision press molds with automation technology which combines the core technologies of I-PEX.

-

Fundamental technologies to meet the needs for automation

Please check out various fundamental technologies which I-PEX possesses to meet the needs for automation.

-

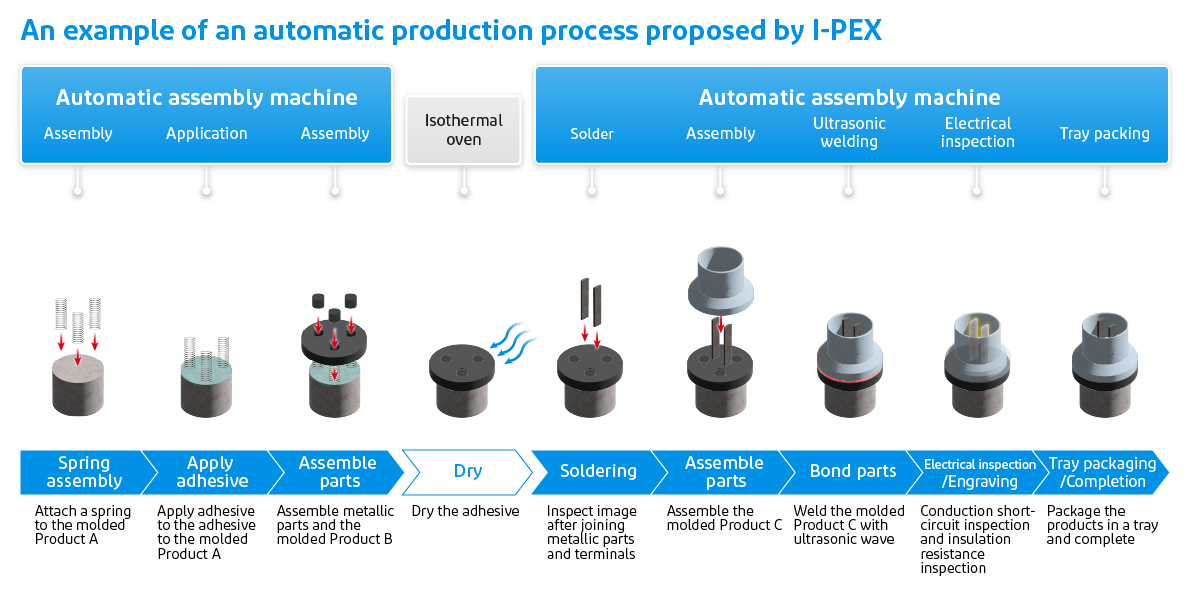

Customized automatic assembly machine for the product

Involvement at the early stage of developing an automatic machine will ease the planning of a fully customized automatic assembly machine..

-

Precision molding molds

I-PEX will offer customers any kinds of solutions related to molds from product design proposals to production of mass-production molds based on our precision processing technology.

-

Proposal of production process and production line

I-PEX, which has been successful in the mass production of various products, will propose to customers the best production process as well as the recipes for production.

Molds/Automation System

Molds/Automation System

-

Invitation to the Robot and Aerospace Festa 2025

- Exhibition

- Connectors

- Molds/Automation System

- Precision Molded Parts

- Sensors

-

Invitation to The Total Solution Exhibition for Electronic Equipment 2025

- Exhibition

- Molds/Automation System

-

Dedicated website launched to accept orders for “Molds and Automation System” in June

- Press Release

- I-PEX Solutions

- Molds/Automation System

- Semiconductor Manufacturing Equipment