Strengths and features of contract manufacturing

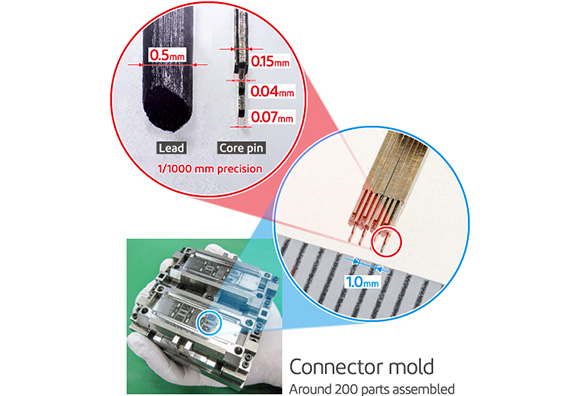

Design optimization through integrated complex molding solutions

We combine tiny parts made with grinding technology to produce high-precision, split-structure molds.

In addition, the interchangeability of each part makes it easier to switch and restore them, thereby ensuring production stability.

By designing and manufacturing molds, press molds and ultimately automatic machines, we can ensure high quality through combining different technologies.

By designing the optimum line arranged for product specifications, production bases, and planned quantities, we are able to realize cost reductions.

Achieve design optimization from the product concept stage

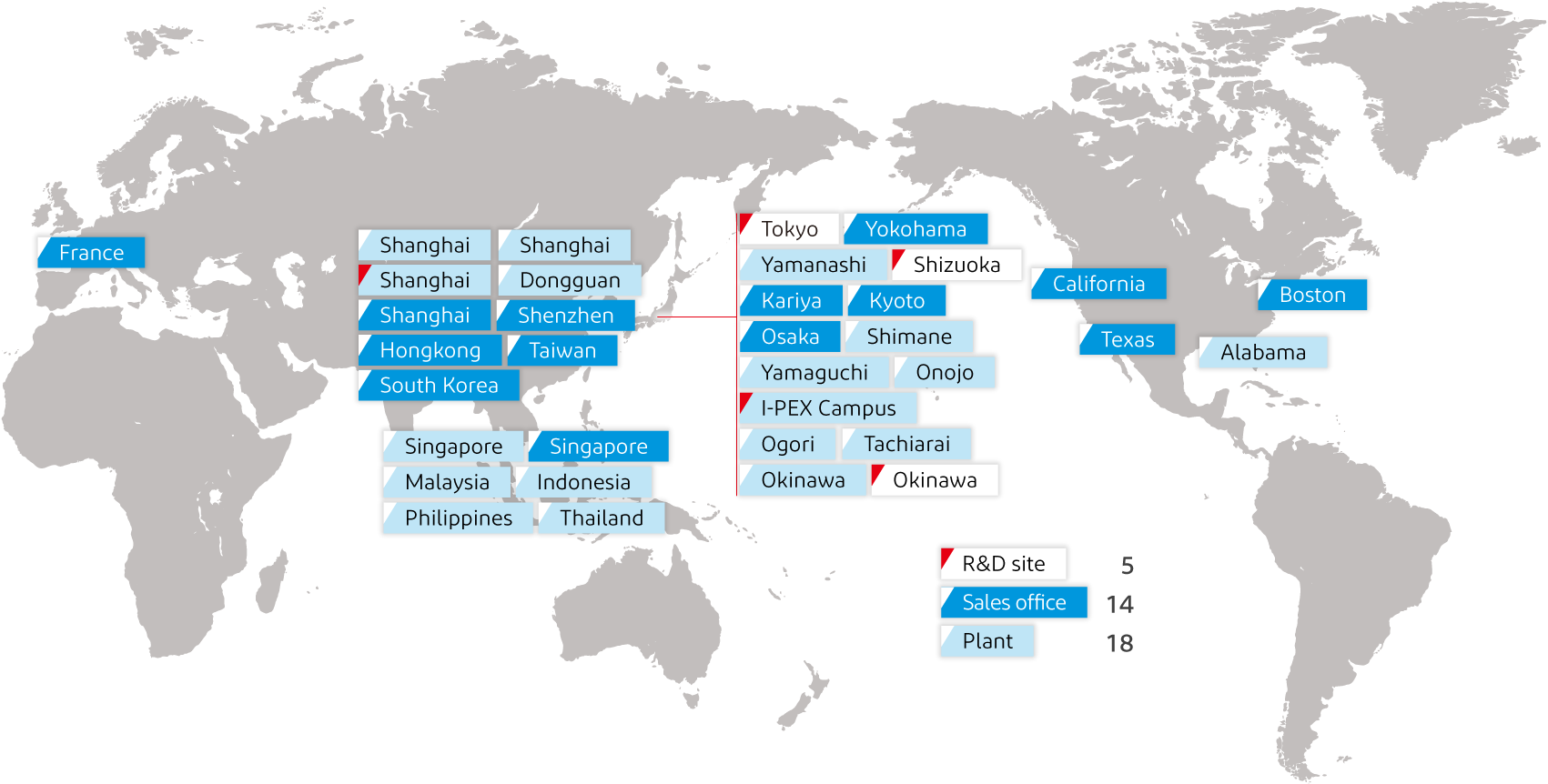

We have 14 sales offices around the world, and receive requests through direct interviews organized by our extensive support system with FAEs*. By providing immediate solutions and suggestions, we can accelerate customers' development period. We cooperate with customers to reduce their total costs.

- ﹡Field Application Engineers (On-site engineers)

Backed by reliable long-term support

We supply 300-million resin and metal composites annually.

With zero market complaints, we are highly valued by our customers.

List of products

Automotive products

-

Custom connectors

We offer custom connectors to meet customer's diverse needs, and contribute to cost reductions through an improved board mounting method and localization.

-

Molded products

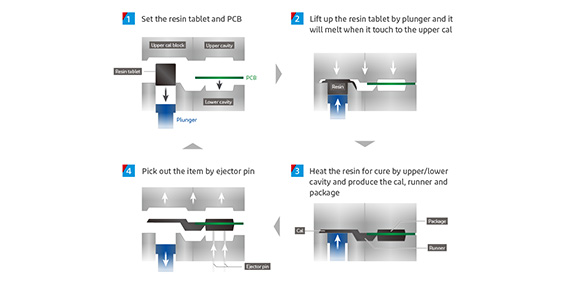

A fully automatic insert molding system has been established that enables collective and stable production of multiple parts including IC chips, metal parts and other parts. With the wealth of technological capabilities we have cultivated in the automotive parts industry for many years, and through our stable production and supply capabilities, we can meet a wide range of needs.

Precision molded parts

-

Precision molding

We can offer proposals for the mass production of precision molded parts, molding of electronic parts, and production of various custom parts.

-

Assembly and contract manufacturing

From the design stage through to assembly, we take on contract manufacturing for products. This is based on the know-how we have cultivated in the mass production of various products, and manufacturing our own equipment.

-

Aerospace components

We supply aircraft engine components to OEMs and MROs that meet stringent aerospace standards.

Precision Molded Parts

Precision Molded Parts

-

Invitation to the Robot and Aerospace Festa 2025

- Exhibition

- Connectors

- Molds/Automation System

- Precision Molded Parts

- Sensors

-

Invitation to The Battery Show South 2025

- I-PEX USA Manufacturing Inc.

- Exhibition

- Precision Molded Parts

- Automotive Components

-

New Product Development by Thermoset Resin Molding Technology

- I-PEX Solutions

- Thermoset Resin

- Automotive Components

- Precision Molded Parts