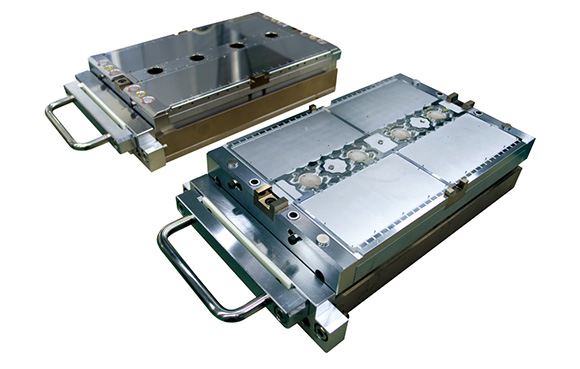

GP Molds

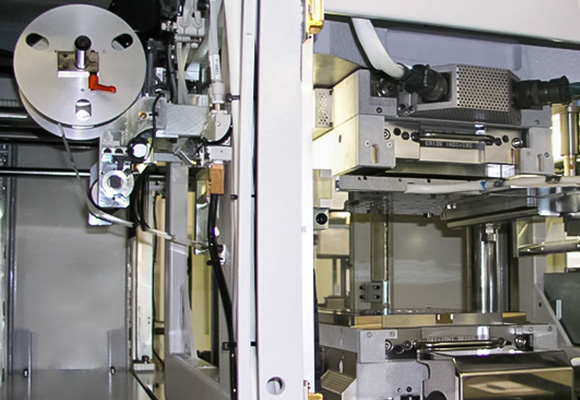

Advanced packaging supported through various molding methods Precision machining technology available to meet customers' needs

We offer high quality molds that are manufactured through precision machining and have excellent durability and compatibility.

A wide range of optional functions can be installed, including "CCFC," which is a transfer compression molding system developed by our company, the Pin Point Gate Molding system (PPG), the Hydraulics Floating Cavity Bar system (HFC), and more. Through this, we can meet customers' diverse needs.

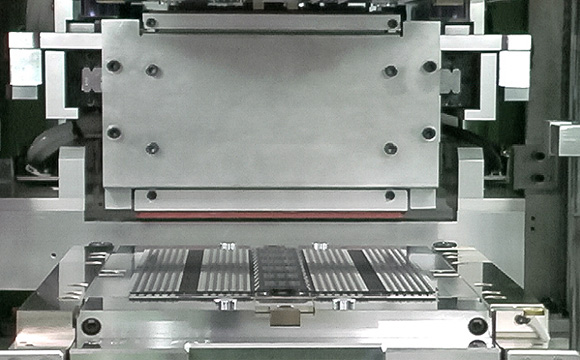

Transfer compression molding system CCFC (Clamping Control Floating Chase)

The transfer compression molding system "CCFC" is our unique technology that combines the benefits of transfer molding and compression molding.

By moving the top cavity of the mold in accordance with the resin filling timing, we can achieve narrow-gap thin molding, which is not possible with conventional transfer molding, and we can also make significant contributions to cost reductions by realizing filmless molding.

Additionally, through spacer replacement, the cavity thickness changing structure allows you to produce differing-thickness QFN package products without changing the mold, reducing mold investment costs and shortening mold replacement loss time.

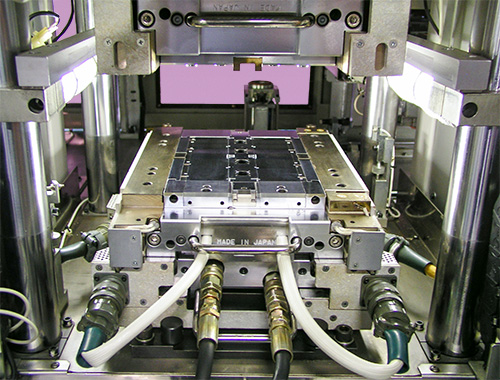

Hydraulic floating cavity bar system HFC (Hydraulic Floating Cavity Bar)

Absorption of BGA board thickness balance with the HFC is the only solution to problems that cannot be solved with a spring or cotter.

Vertically variable hydraulic cavity bars provide optimum clamping. The high pressure clamp can also be controlled by a soft clamp.

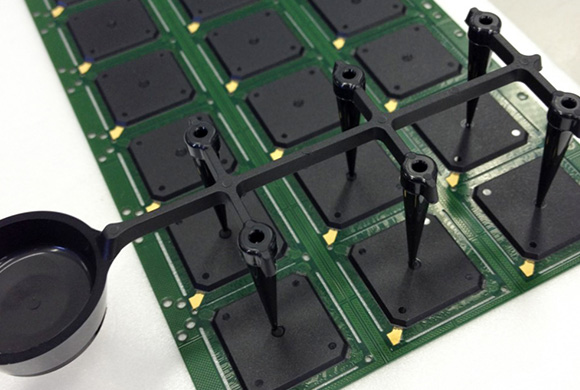

Pin point gate molding system PPG (Pin Point Gate Molding)

The Pin Point Gate is not only a solution to narrow-pitch wire products that require wire-flow measures, but it is also a special technology that is necessary to accommodate high-density frames.

Dual Pot Mold Chase

Dual Pot enables the use of large-diameter resins required for large-module molding. You can also choose a mini tablet with excellent melting stability and reduce wire displacement.

Prevents voids from occurring by a patented cull heater that manages the heat loss of the mold due to resin loading.

VAM(Vacuum Assisted Molding)

In forming a new type of package, such as a stacked die package, VAM technology prevents voids and non-filling by decompressing the cavity and injecting resin.

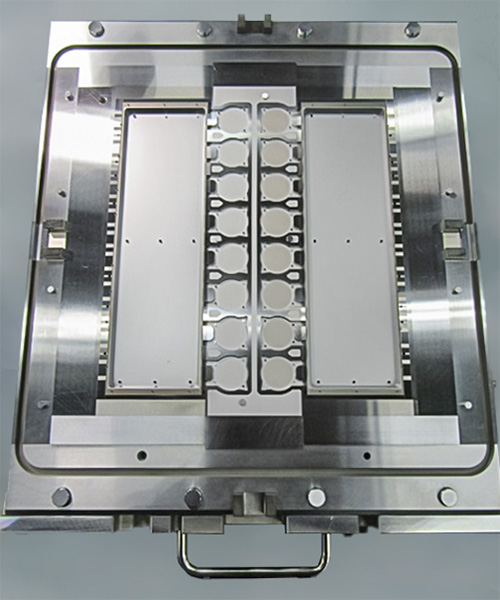

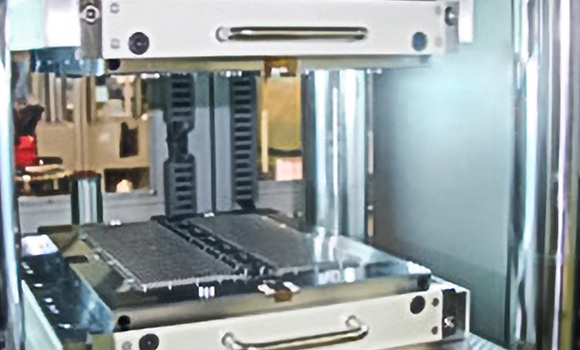

FAM(Film Assisted Molding)

Sensor molding for die exposed packages and exposed heat sink molding for power devices are realized through FAM technology using film.

High Density Leadframe Molding (HDLF)

The increasing density of frames continues to expand, and the market demands larger frames.

The SP series is available in 80-tons, 120-tons and 170-tons, and can accommodate frames up to 110mm x 300mm in size.

4SPC(4 Strips per chase Molding)

You can effectively use your current thin lead frame with the concept of 4SPC for molding. It is possible to increase production volume without modification of other processes. (Maximum lead frame size: 31mm x 270mm)

List of products

Semiconductor molding machines

-

GP-PRO SP Series

An automatic molding system suitable for mass production.

The company has implemented thorough dust protection to enhance reliability and meets a wide range of needs for high quality, from consumer ICs to automotive ICs and passive components.

-

GP-PRO sf Series

A compact, full-automatic molding system dedicated to high-mix low-volume production.

The sf40 (one-strip type), and two sf120 models (two-strip type) are available.

-

GP-PRO sa Series

Automatically transfers the lead frame and resin to the mold which are then automatically processed.

After molding, the product is removed manually in a two-strip semi-automatic molding system.

-

GP-PRO LAB Series

A manual molding system that offers a wide range of options from development to specialized applications.

-

S・Pot

A molding machine for device development, which uses a compact mold. It is tabletop-ready, easy-to-handle, and has a small form-factor. Prototype molding can be made in a short period of time and at a low price, making it a flexible device for developing new packages.

Semiconductor related equipment

-

TS-PRO

TS-PRO is a machine that is a global standard for applying Quad Flat No leaded package (QFN) back tape.

By applying back tape after wire bonding, the problems that occur relating to tape are solved, and it contributes to substantial cost reductions.

-

DS-PRO

A machine that automatically strips QFN back tape. Compatible with both slit and stack magazines. The machine automatically strips off tape that has been securely applied.