Assembly and contract manufacturing

From the design stage through to assembly, we take on contract manufacturing for products. This is based on the know-how we have cultivated in the mass production of automotive parts and connectors, and the manufacturing of production equipment for use in our company.

By employing our domestic and overseas networks, we are able to provide products using an optimal system.

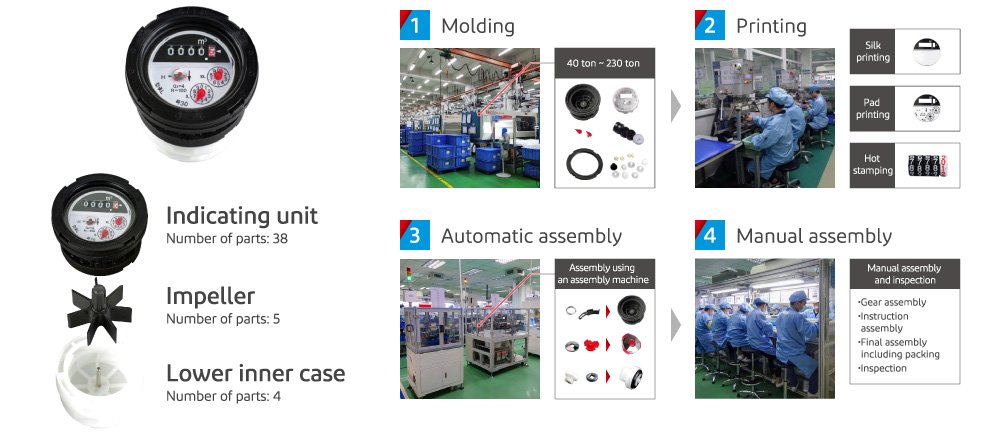

Case 1: Water meters

The central part of a water meter requires precise and stable operation in harsh environments where high resistance to water and dust are necessary.

We produce and supply approximately 50 parts through a variety of processes, including welding and press fitting, printing and pasting.

Case 2: Forensic analysis devices

We supply microfluidic devices used for forensic analysis, which have combinations of approximately 300 materials and chemicals such as molded circuits, filters and valves.

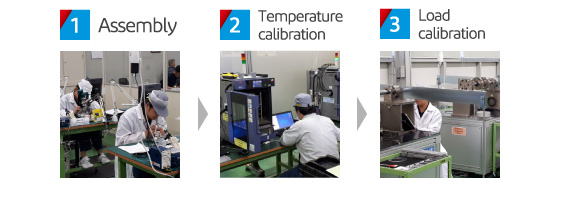

Case 3: Torque sensors

Employment case

Process

The sensor "ESTORQ" detects and controls the torque generated when various robots and automatic assembly devices developed in-house carry out rotational movements.

It incorporates precision mechanical and electric components/parts, and performs operations including various calibrations, precision inspections, and characteristic confirmation.

List of products

Automotive products

-

Custom connectors

We offer custom connectors to meet customer's diverse needs, and contribute to cost reductions through an improved board mounting method and localization.

-

Molded products

A fully automatic insert molding system has been established that enables collective and stable production of multiple parts including IC chips, metal parts and other parts. With the wealth of technological capabilities we have cultivated in the automotive parts industry for many years, and through our stable production and supply capabilities, we can meet a wide range of needs.

-

Automotive connectors

We propose connectors for automobiles, including ultra-small SMT connectors and new press-fit terminals that we have developed.

Precision molded parts

Precision Molded Parts

Precision Molded Parts

-

Invitation to the Robot and Aerospace Festa 2025

- Exhibition

- Connectors

- Molds/Automation System

- Precision Molded Parts

- Sensors

-

Invitation to The Battery Show South 2025

- I-PEX USA Manufacturing Inc.

- Exhibition

- Precision Molded Parts

- Automotive Components

-

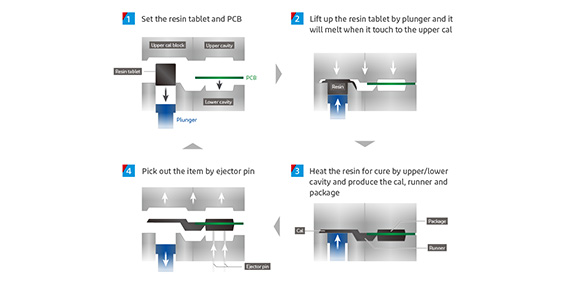

New Product Development by Thermoset Resin Molding Technology

- I-PEX Solutions

- Thermoset Resin

- Automotive Components

- Precision Molded Parts