What is an automatic molding machine

The automatic molding machine is a device that automatically carries out the following: automatic transfer and lining up of the lead frame installed on the magazine, conducting sealing (molding), removing cull and gate from it, and then inserting it into a magazine.

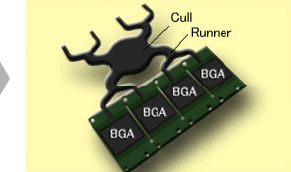

Semiconductor molding process (for Ball Grid Array (BGA) type)

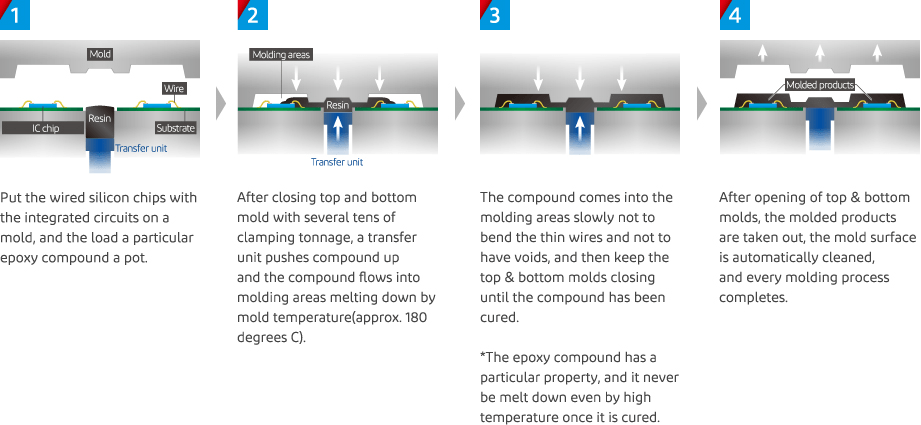

Semiconductor molding procedures

- 1.Put the wired silicon chips with the integrated circuits on a mold, and the load a particular epoxy compound a pot.

- 2.After closing top and bottom mold with several tens of clamping tonnage, a transfer unit pushes compound up and the compound flows into molding areas melting down by mold temperature(approx. 180 degrees C).

- 3.The compound comes into the molding areas slowly not to bend the thin wires and not to have voids, and then keep the top & bottom molds closing until the compound has been cured.

*The epoxy compound has a particular property, and it never be melt down even by high temperature once it is cured. - 4.After opening of top & bottom molds, the molded products are taken out, the mold surface is automatically cleaned, and every molding process completes.

Molding completed

The molded product is separated from the runner, metal protrusions for connection are attached to the back side in the next process, and then cut into individual pieces to complete the process.

The finished semiconductors are used in many electronic devices such as PCs, digital cameras, cell phones, and game consoles.