What is QFN tape

QFN back tape

For QFN and DFN packages, back tape is applied to the back-side of the lead frame to prevent resin leakage during molding.

The back tape uses a highly heat-resistant polyimide film. In addition, a silicone-based tape adhesive is the most common type.

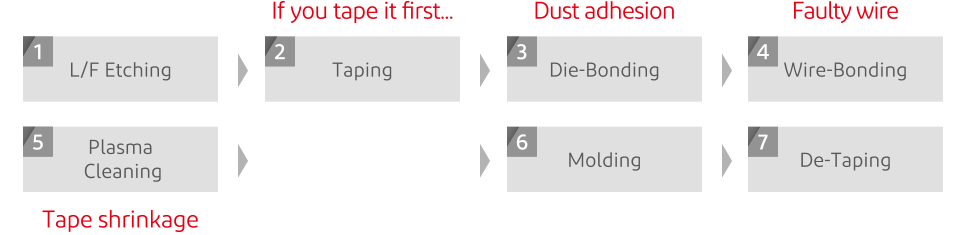

There are two types of taping processes, the "pre-tape method" and the "post-implementation tape method," depending on the order.

Pre-tape method

This is a method where the lead frame is used with the back tape applied by the lead frame manufacturer.

There is a risk that foreign substances can easily enter the package due to die-bonding and wire-bonding that is carried out on a frame that has already been taped. In addition, because wire bonding is performed on a frame that has been taped, there is a risk that the tape will become elastic and the copper wire will not be properly bonded.

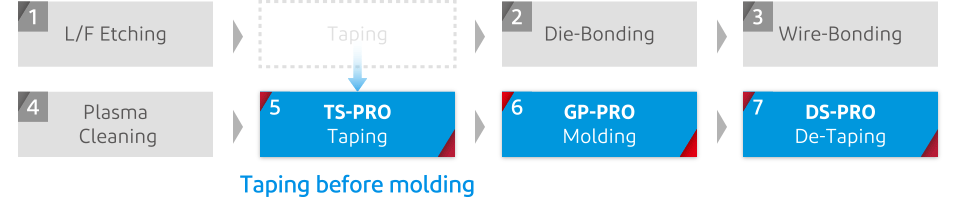

Post-implementation tape method

A method where the conventional lead frame is purchased and the back tape is applied just before molding.

Taping after plasma cleaning significantly reduces the risk of contamination by foreign substances. Wire-bonding is also performed to the conventional frame, allowing stable bonding to copper wire.

For taping equipment for the post-implementation tape method, TS-PRO which utilizes our own taping technology has gained the de-facto standard.

We also offer a series of solutions for post-QFN taping (TS-PRO), molding (GP-PRO), and tape peeling (DS-PRO).