Fundamental technologies to meet the needs for automation

I-PEX uses our fundamental strength in precision processing in combination with precision molding molds, precision press molds, and automation technology to propose ways to meet the various needs for automation.

Major fundamental technologies

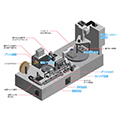

Lead terminal processing by press mold

Terminals can be bent and cut in a device by incorporating terminal press processing in the device. The processes can be reduced by taking the coil materials automatically into the device with the reel set.

Setting to the molding mold by insert robot

A Robot sets the aligned terminals into the mold.

I-PEX will be responsible for planning devices, adjusting delivery dates, adjusting machines after installation, and fixing defects for our customers.

Assemble O-rings and screws to the molded products

Various assembly processes such as mounting O-rings and screws to the molded products can be incorporated into the device. Cost can be reduced because various processes can be completed in a single device.

Inspection stage to determine the quality of the products

An inspection stage can be arranged to determine the quality of the products in the case of lead inspections, seal inspections, and unfilled inspections of molded and assembled products. Arranging an inspection stage will allow the storing of only good products in product trays.

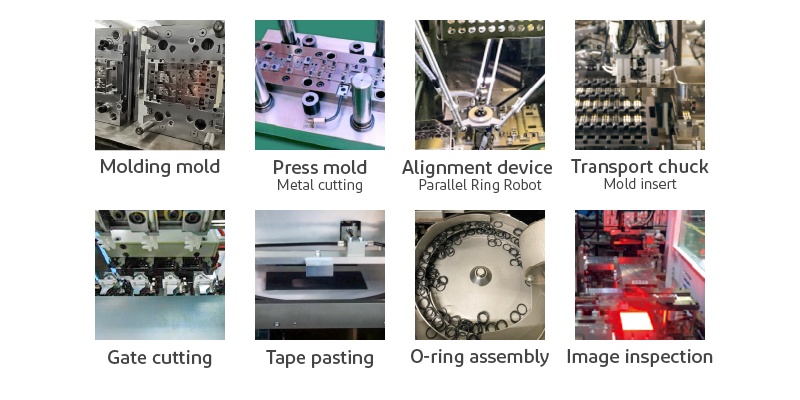

An example of various processes of installation in an automation machine

Our mass production devices with precision processing, precision molding, and automatic machine technologies will enable customers to adopt the following processes into their production.

- Molding mold

- Image inspection

- Metal cutting

- Transport chuck (mold insert)

- Gate cutting

- Tape pasting

- Assemble O-rings

- Alignment device (parallel link robot)

Please contact us for any further questions.

List of Solutions

-

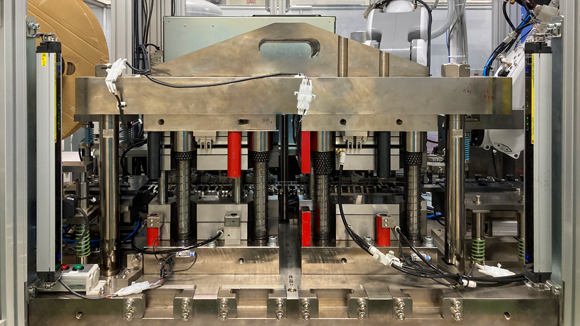

All-in-one system including molds and automatic machines

Your production will be fully automated with a single piece of equipment by aggregating precision molding molds and precision press molds with automation technology which combines the core technologies of I-PEX.

-

Customized automatic assembly machine for the product

Involvement at the early stage of developing an automatic machine will ease the planning of a fully customized automatic assembly machine.

-

Precision molding molds

I-PEX will offer customers any kinds of solutions related to molds from product design proposals to production of mass-production molds based on our precision processing technology.

-

Proposal of production process and production line

I-PEX, which has been successful in the mass production of various products, will propose to customers the best production process as well as the recipes for production.