GP-PRO sf Series

Realization of high cost performance

A standard machine for high-mix low-volume production

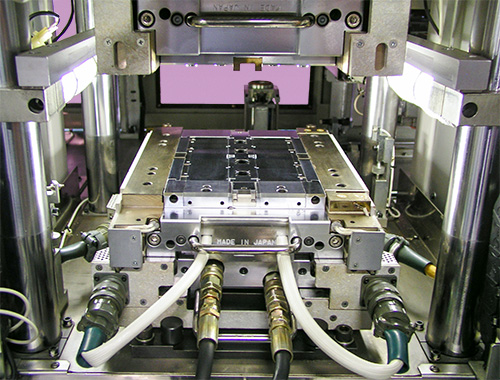

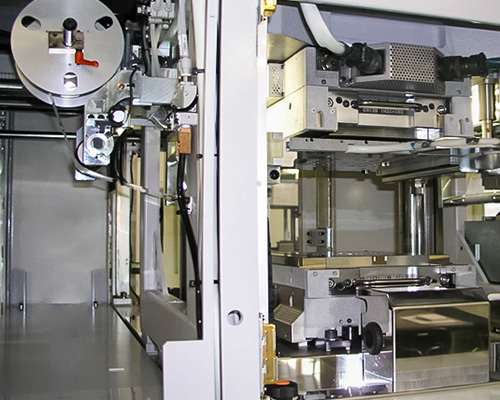

The "sf series" was developed as compact and full-automatic molding equipment exclusively for one pressing to meet the needs of low-volume production of high-value-added products. Two types are available: The one-strip sf40, and the two-strip sf120.

This machine realizes high cost performance for a wide range of customer needs that are compact and have excellent maintainability.

Feature 1:1 High cost performance through one-press dedicated equipment

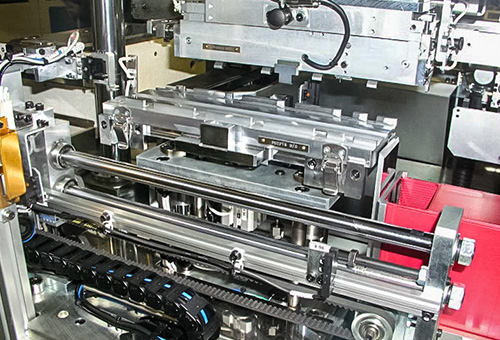

One-press dedicated machines and unique loader mechanisms realized automatic molding with lower equipment costs. HD lead frames (75 mm x 270 mm) can be also supported.

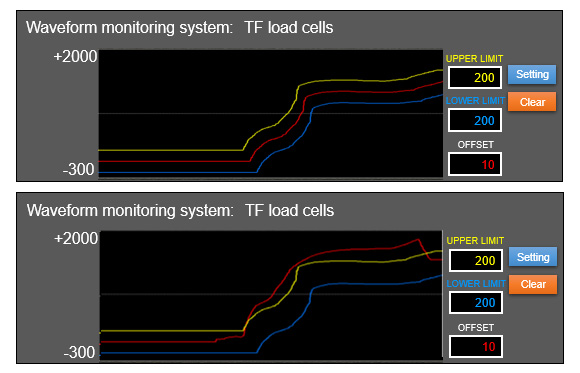

Feature 2: IoT ready for stable production

Real-time visibility into operation conditions required by smart factories is realized. (Optional)

Always-on monitoring provides alerts in advance to eliminate the risk of unexpected machine stoppages. We support customers' predictive maintenance activities.

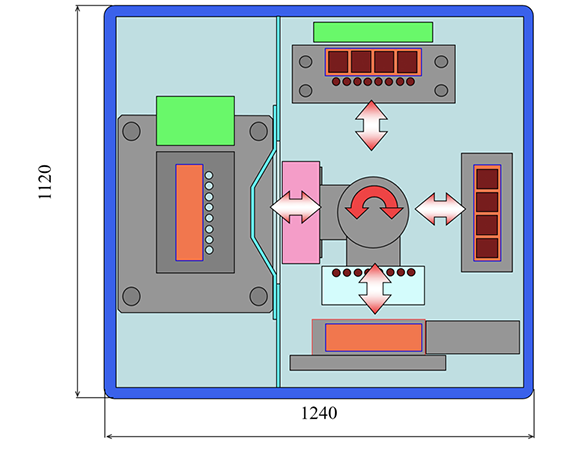

Feature 3: Space saving by optimized unit placement

The sf40 has realized 1.4 square meters in space savings (1240 mm x 1120 mm), despite the fact that it is a fully automatic molding machine.

We also supply magazines for tablets that are easy to change resins with, to accommodate a wide variety of products, such as resin differences. (Optional)

Feature 4: Wide range of standard equipment

Pre-heater

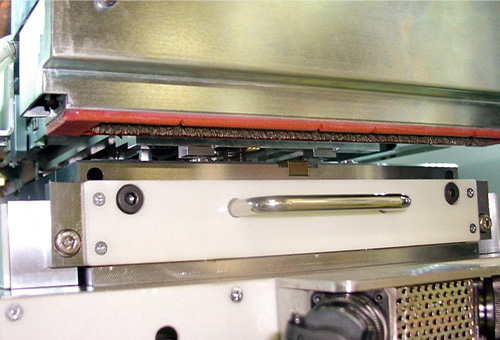

Powerful mold cleaner with rotating brush

Feature 5: A variety of molding options

HFC (bottom-mold movable CAV system)

VAM (vacuum assisted molding)

FAM (Film assisted system)

Specifications

| Clamp Force | Model Name(press) | Machine Size(mm) | Weight | Max. L/F Size(mm) | |

|---|---|---|---|---|---|

| 120ton | GP-PRO sf120 | (1press) | W:1510×L:1350×H:1880 | 3.8ton | 75×270 |

| 40ton | GP-PRO sf40 | (1press) | W:1200×L:1100×H:1820 | 2.5ton | |

List of products

Semiconductor molding machines

-

GP-PRO SP Series

An automatic molding system suitable for mass production.

The company has implemented thorough dust protection to enhance reliability and meets a wide range of needs for high quality, from consumer ICs to automotive ICs and passive components.

-

GP-PRO sa Series

Automatically transfers the lead frame and resin to the mold which are then automatically processed.

After molding, the product is removed manually in a two-strip semi-automatic molding system.

-

GP-PRO LAB Series

A manual molding system that offers a wide range of options from development to specialized applications.

-

S・Pot

A molding machine for device development, which uses a compact mold. It is tabletop-ready, easy-to-handle, and has a small form-factor. Prototype molding can be made in a short period of time and at a low price, making it a flexible device for developing new packages.

-

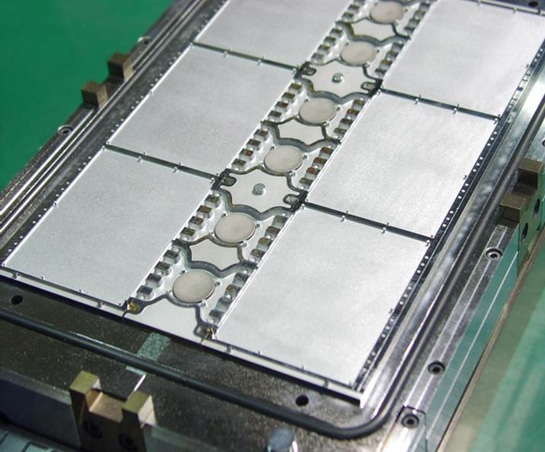

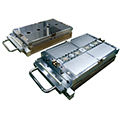

GP Molds

Precision molds for semiconductor packaging. Our unique Clamp Control Floating Chase (CCFC) and other mechanisms are available to handle all packages.

Semiconductor related equipment

-

TS-PRO

TS-PRO is a machine that is a global standard for applying Quad Flat No leaded package (QFN) back tape.

By applying back tape after wire bonding, the problems that occur relating to tape are solved, and it contributes to substantial cost reductions.

-

DS-PRO

A machine that automatically strips QFN back tape. Compatible with both slit and stack magazines. The machine automatically strips off tape that has been securely applied.