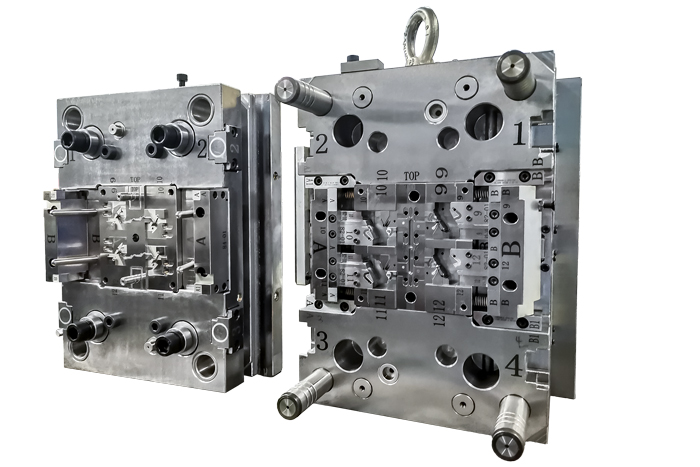

Precision molding molds

We offer customers all kinds of solutions regarding molds based on I-PEX's precision processing technology, from product design proposal to the production of mass-production molds.

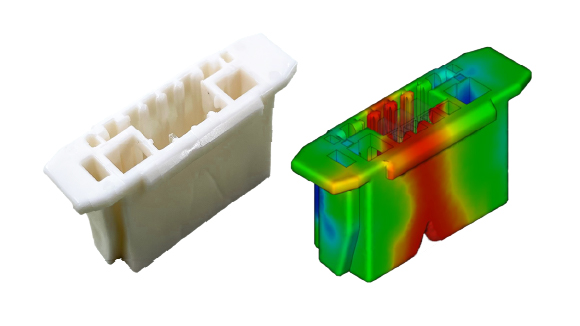

Proposal and analysis of molded product design

I-PEX's mass production track record of various kinds of molded products enables us to optimize the structure and rigidity of the product design to meet the requirements by structural analysis. We also propose customers a product design that promises stable mass production by examining mold defects with flow analysis in advance.

Proposal for mold specifications to meet customers needs

We have manufactured molds with high precision requirements based on the "module system" mold crafting method with a total division structure and all machine processing to realize high precision molds ever since the foundation of Dai-ichi Seiko.

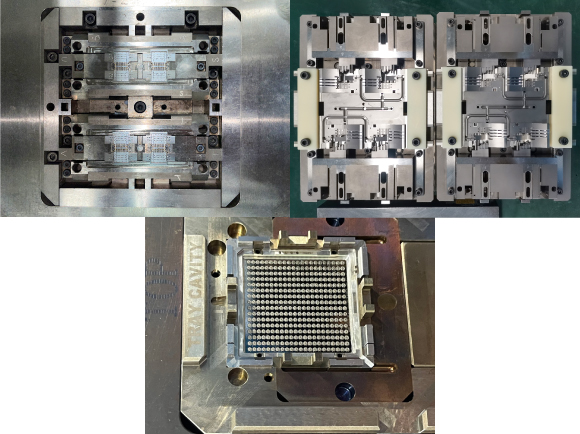

We offer customers all kinds of molds to meet requirements for the products, such as high-precision molding molds, insert molds, two-colored molds, super engineering plastic molds, multi-pot transfer molding die, etc.

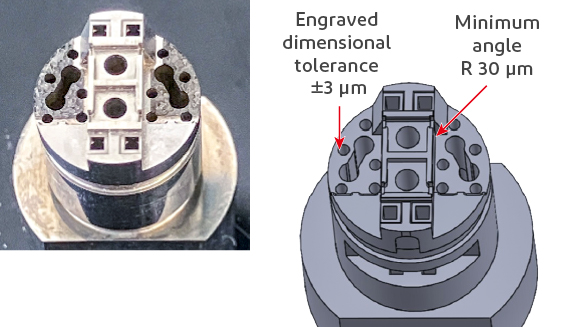

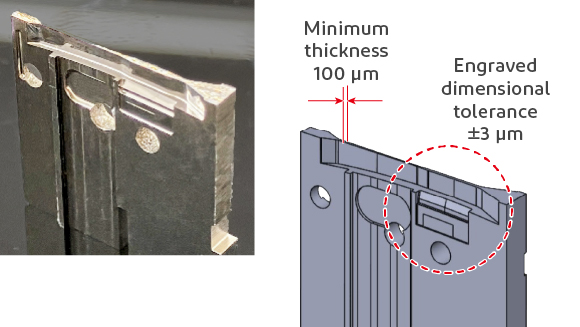

Insert mold (top left), two-colored mold (top right), super engineering plastic mold (bottom)

Insert mold (top left), two-colored mold (top right), super engineering plastic mold (bottom)High-precision processing technology for the realization of precision molds

We have the processing methods necessary to manufacture high-precision molds, such as electrical discharge, grinding, and machining centers.

Direct engraving enables process reduction, and electrical discharge machining enables the manufacturing and production of the shapes. This used to be impossible before by electrical discharge and ultra-fine wire electric discharge.

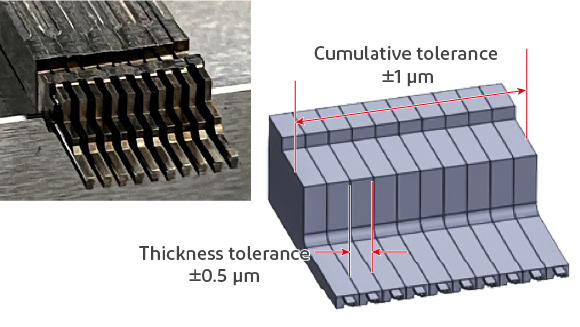

Cumulative processing technology with zero variation

Our technology enables reproductivity of high precision mold assembly by controlling ±1μ in metal variation as well as processing micron order of single metal parts.

Electrical discharge technology with high accuracy

All kinds of complex shapes can be produced by electrical discharge machining. Our technology will accommodate the high-precision dimensional accuracy as well as a minimum R=30μ.

Direct precision processing technology

We adopt direct engraving processing by machining to produce mold parts with high-precision. We produce parts with high-precision and reproducibility in a short period of time.

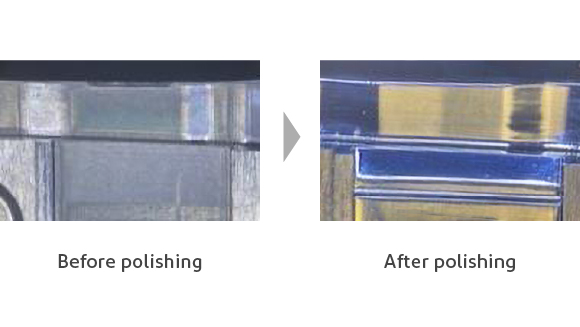

Polishing and fitting to actual parts to meet the needs

We will accommodate surface polish processing to meet the purpose of use. Manual polishing and fitting to actual parts at the final stage of processing enables us to produce the mold with high-quality.

List of Solutions

-

All-in-one system including molds and automatic machines

Your production will be fully automated with a single piece of equipment by aggregating precision molding molds and precision press molds with automation technology which combines the core technologies of I-PEX.

-

Fundamental technologies to meet the needs for automation

Please check out various fundamental technologies which I-PEX possesses to meet the needs for automation.

-

Customized automatic assembly machine for the product

Involvement at the early stage of developing an automatic machine will ease the planning of a fully customized automatic assembly machine.

-

Proposal of production process and production line

I-PEX, which has been successful in the mass production of various products, will propose to customers the best production process as well as the recipes for production.